20 32 6 Oil Seal - High-Quality Sealing Solutions

Understanding the 20 32 6 Oil Seal Importance and Applications

Oil seals, also known as liquid seals or grease seals, play a crucial role in machinery and automotive systems. Among the various types of oil seals, the 20 32 6 oil seal stands out due to its unique specifications and applications.

An oil seal is designed to prevent the leakage of lubricants, and simultaneously, keep contaminants like dirt and dust from entering the system. The 20 32 6 oil seal is specifically tailored to meet certain dimensional criteria, which often represent the seal’s inner diameter, outer diameter, and width. Understanding these dimensions is imperative for ensuring proper fitting and functionality.

The designation 20 32 6 likely indicates specific measurements associated with the seal typically, the first number represents the inside diameter, the second signifies the outside diameter, and the last number indicates the width or thickness of the seal. For instance, in this case, the inner diameter is 20 mm, the outer diameter is 32 mm, and the width is 6 mm. These dimensions confirm that the seal is suitable for various industrial applications where standard sizes may not provide an effective barrier.

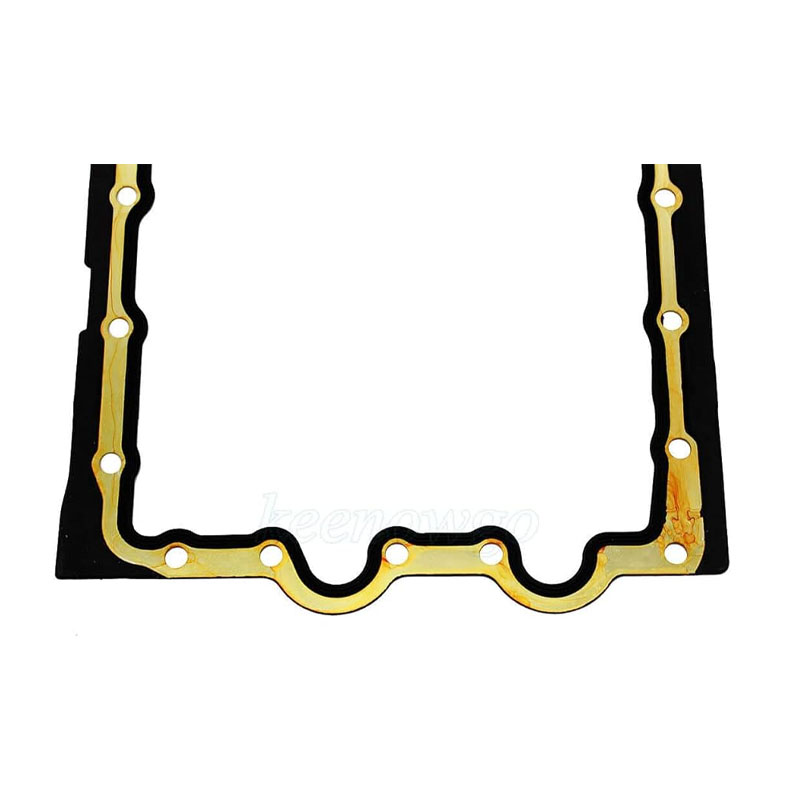

20 32 6 oil seal

The material composition of the 20 32 6 oil seal is another key factor. Most oil seals are manufactured from synthetic rubber compounds or thermoplastics, which provide excellent resistance to temperature fluctuations, oils, and other chemicals. This durability is vital in applications ranging from automotive engines to hydraulic systems where high performance and reliability are expected.

Moreover, the 20 32 6 oil seal is often employed in rotating equipment such as pumps and motors. In these scenarios, the seal's ability to withstand significant pressure and prevent leakage is invaluable. When properly installed, this oil seal ensures that machinery operates smoothly by maintaining the necessary lubrication within critical components while safeguarding against contamination that could lead to wear and tear.

Maintenance of oil seals, including the 20 32 6 variant, is equally important. Regular inspections and timely replacements can prevent catastrophic failures in machinery. Signs that an oil seal may need replacement include visible leaks, unusual noises from machinery, or an increase in operating temperature, all of which can indicate a loss of lubrication or the ingress of contaminants.

In conclusion, the 20 32 6 oil seal is a vital component in various mechanical systems, ensuring efficiency and longevity. Its specific measurements and material properties cater to a wide range of applications, from automotive to industrial machinery. Understanding the significance of such seals and maintaining them properly is crucial for enhancing equipment performance and minimizing downtime. As technology advances, innovations in oil seal design will likely continue, further improving their effectiveness and applications in the ever-evolving world of machinery.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories