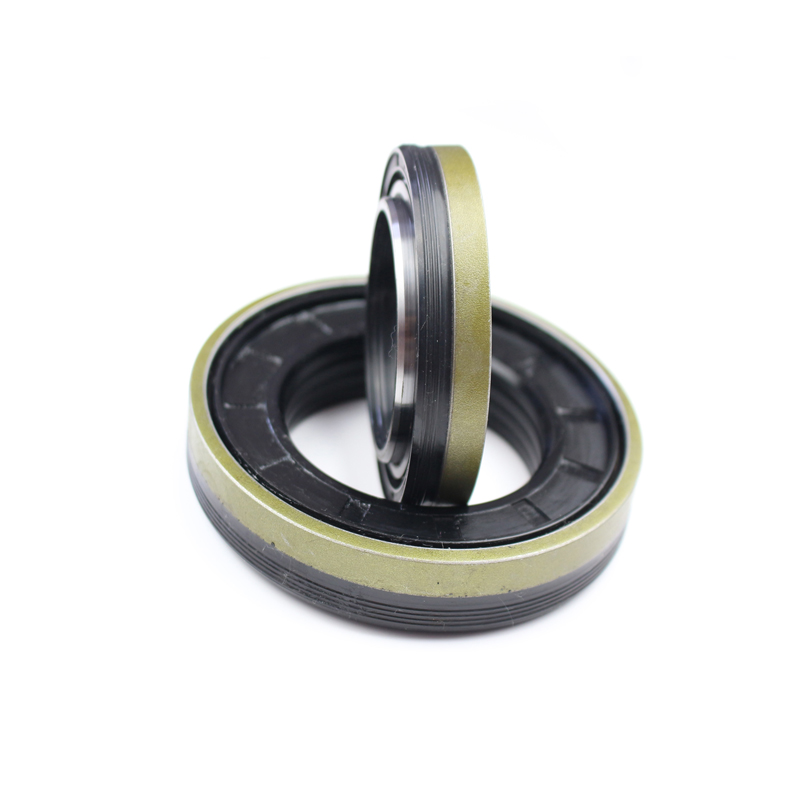

max spare oil seal

Understanding Max % Spare Oil Seal Importance and Applications

In the world of machinery and industrial applications, the reliability and efficiency of equipment are paramount. One essential component that plays a critical role in maintaining machinery performance is the oil seal. In particular, the concept of max % spare oil seal provides valuable insights into inventory management and operational efficiency within industries that rely heavily on rotating machinery.

What is an Oil Seal?

An oil seal is a device used to seal the interface between rotating and stationary parts, preventing the leakage of lubricants and protecting the inside assembly from contaminants. Common materials for oil seals include rubber, silicone, and polyurethane. These seals come in various designs and configurations to suit specific applications, ranging from automotive to industrial machinery.

Max % Spare Oil Seal Definition

The term max % spare oil seal refers to the maximum percentage of spare oil seals that organizations aim to keep in inventory compared to the total need for these seals. This percentage is crucial in maintenance planning and inventory management, ensuring that businesses are prepared for any unexpected failures or maintenance needs without incurring excessive stockholding costs.

Importance of Maintaining Spare Oil Seals

1. Operational Continuity Machinery often operates under severe conditions, making them susceptible to wear and tear. Having spare oil seals readily available ensures that repairs can be conducted swiftly, minimizing downtime and maintaining operational continuity.

2. Lowering Emergency Costs Without a sufficient inventory of spare parts, a machinery failure could lead to costly emergency procurement. Organizations can avoid inflated prices for expedited shipping and last-minute orders by maintaining a strategic stock of spare oil seals.

max spare oil seal

3. Extended Equipment Life Regularly replacing worn oil seals helps prevent oil leakage and contamination. This proactive maintenance practice extends the life of machinery, reducing the frequency and cost associated with complete overhauls or replacements.

4. Optimizing Maintenance Strategies By analyzing usage patterns and establishing the max % spare oil seal, organizations can develop more effective predictive maintenance strategies. Knowing when and how many seals to replace can help in scheduling maintenance during planned downtimes rather than reactive fixes during emergencies.

Factors Influencing Max % Spare Oil Seal

1. Nature of Operations Industries with high operational intensity, such as manufacturing and mining, may require a higher percentage of spare seals to ensure uninterrupted functioning. Conversely, less demanding operations might need fewer spares.

2. Lead Time for Replacements If obtaining replacement seals involves lengthy lead times, it becomes crucial to maintain a larger inventory to prevent operational disruptions.

3. Historical Failure Data Analyzing past performance data, including the frequency of seal failures and mean time between failures (MTBF), helps businesses determine the optimal percentage of spare seals to hold.

4. Budget Constraints Financial considerations also play a significant role in how many spare oil seals a company can afford to maintain. Organizations must balance carrying enough inventory to avoid downtime while keeping costs manageable.

Conclusion

Understanding the concept of max % spare oil seal is vital for any business involved in operations reliant on rotating machinery. By maintaining an appropriate inventory of spare oil seals, organizations can enhance operational efficiency, minimize costs associated with downtime, and prolong the lifespan of their equipment. Ultimately, effective inventory management of oil seals not only safeguards the machinery but also contributes to the overall productivity and success of a business. As industries face challenges such as fluctuating demand and supply chain disruptions, the strategic management of spare parts, including oil seals, becomes increasingly important for sustainable operational excellence.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories