Understanding Crankshaft Main Bearing Seals and Their Importance in Engine Performance

Understanding Crankshaft Main Bearing Seals Importance and Maintenance

The crankshaft main bearing seal is a vital component in the internal combustion engine's assembly, playing a crucial role in maintaining engine performance and longevity. This seal, often referred to as the rear main seal, is located at the rear of the crankshaft, where it exits the engine block and connects to the transmission. Its primary function is to prevent engine oil from leaking out of the crankcase while keeping contaminants such as dirt and debris from entering.

The Function of Crankshaft Main Bearing Seals

The crankshaft operates under extreme conditions, subjected to high temperatures and pressures. The main bearing seal creates a barrier that contains the lubricating oil essential for the smooth operation of the engine's moving parts. By preventing oil leaks, it helps maintain optimal oil pressure, contributing to the efficient operation of the engine. Additionally, the seal protects the internal components from external contaminants, which could lead to premature wear and damage.

The crankshaft main bearing seal is typically made from durable materials such as rubber or silicone, designed to withstand high temperatures and the constant friction generated by the crankshaft's rotation. Over time, however, these seals can wear out due to thermal fatigue, chemical exposure from engine oil, and the constant motion of the crankshaft. Signs of a failing main bearing seal include oil leaks, increased engine noise, and a drop in oil pressure.

Common Issues and Diagnosis

One of the most common problems associated with crankshaft main bearing seals is leaking oil. A visual inspection might reveal oil pooling underneath the vehicle or an oil slick on the engine's exterior. It is vital to address oil leaks promptly, as low oil levels can lead to severe engine damage. Additionally, an engine with low oil may exhibit increased temperature due to inadequate lubrication.

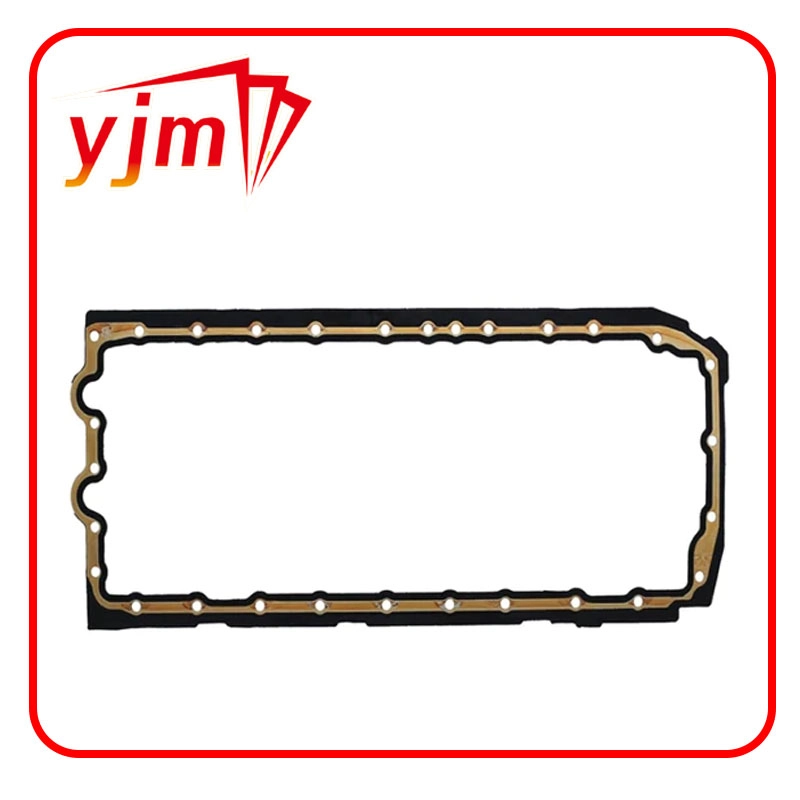

crankshaft main bearing seal

Mechanics often perform a series of diagnostic tests to determine the condition of the main bearing seal. Pressure tests can gauge the internal pressure of the crankcase, while visual inspections may unveil cracks or signs of wear on the seal itself. In some cases, the use of dyes in engine oil can help identify the exact source of a leak, facilitating targeted repairs.

Maintenance and Replacement

Preventative maintenance is key to prolonging the life of the crankshaft main bearing seal. Regular oil changes and the use of high-quality lubricants can reduce wear and extend the longevity of the seal. Engine oil additives designed to condition seals may also be beneficial, ensuring they remain pliable and durable over time.

When a crankshaft main bearing seal fails, timely replacement is critical. This process often involves significant labor, as the engine must be partially disassembled to access the seal. It is essential for mechanics to follow manufacturer specifications for both the seal material and installation procedures. Proper torque specifications must be adhered to, as improper installation can lead to premature seal failure.

Conclusion

In summary, the crankshaft main bearing seal is an integral component of the engine, vital for maintaining oil integrity and overall engine health. Regular maintenance and prompt attention to signs of wear can prevent significant issues and extend the lifespan of the engine. Understanding the function, common problems, and necessary maintenance for the crankshaft main bearing seal is essential for anyone who wishes to ensure optimal performance of their vehicle. By prioritizing these aspects, vehicle owners can keep their engines running smoothly, safeguarding their investment and enhancing the driving experience.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories