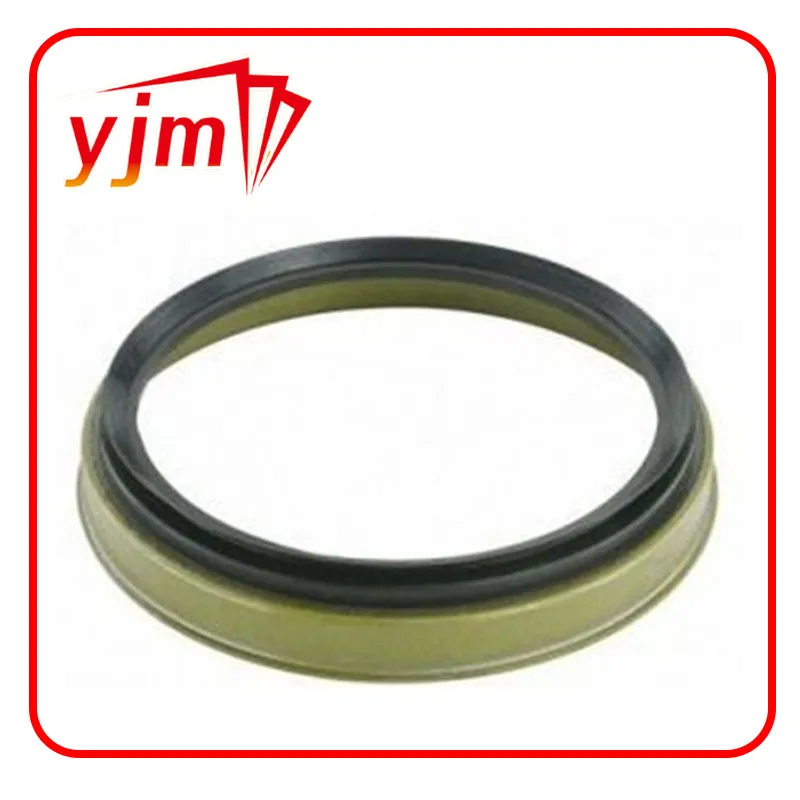

o ring 85mm

The role of O-rings in complex machinery underlines their authoritative presence in industrial applications. Take hydraulic systems as an example; the 85mm O-ring is a common choice for maintaining the pressure integrity in pistons or valves, ensuring safe and efficient operation. Failure of such a seal can result in system leaks, decreased efficiency, and potential safety hazards. Trust in O-ring manufacturers that meet stringent industrial standards is critical, ensuring that each ring performs consistently under pressure. Having years of firsthand experience in working with O-rings establishes a deep understanding of their functional importance. Consulting authoritative guides and working closely with O-ring manufacturers grants further insight into innovations and improvements in this field. These manufacturers are continuously pushing advancements in material science, developing compounds that provide enhanced resistance to wear, chemical degradation, and extreme temperature shifts, ensuring that the 85mm O-ring remains a reliable component in the most challenging conditions. Building trust in O-ring selection involves sourcing from reputable suppliers who adhere to rigorous quality control standards. A buyer's confidence is strengthened by certifications such as ISO 9001, which guarantees that the products meet consistent quality benchmarks. Engaging in partnerships with suppliers that exhibit expertise and demonstrate a commitment to delivering high-quality, durable O-rings assures end-users that their operational needs will be met. Ultimately, the 85mm O-ring is not just a simple sealing device; it is a testament to engineering precision and reliability. When expertly crafted and correctly applied, it serves as a guardian against leaks and failures, reinforcing its place as a cornerstone of mechanical efficiency and safety. For industries relying on flawless performance, the 85mm O-ring is indeed indispensable, showcasing a synergy of expertise, authority, and trustworthiness in modern engineering practices.

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

-

The Importance of Heavy Duty Seals in Industrial and Residential Applications

News Jul.30,2025

-

Exploring Industrial Oil Seals: From Felt Oil Seals to TTO and CFW Solutions

News Jul.30,2025

-

Essential Guide to Oil Seals: From Radial to Metal-Cased Seals for Industrial Reliability

News Jul.30,2025

-

Choosing the Right Oil Seals and Gaskets for Industrial and Automotive Applications

News Jul.30,2025

-

Cassette Seals: Durable Sealing Solutions for Harsh Environments

News Jul.30,2025

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

Products categories