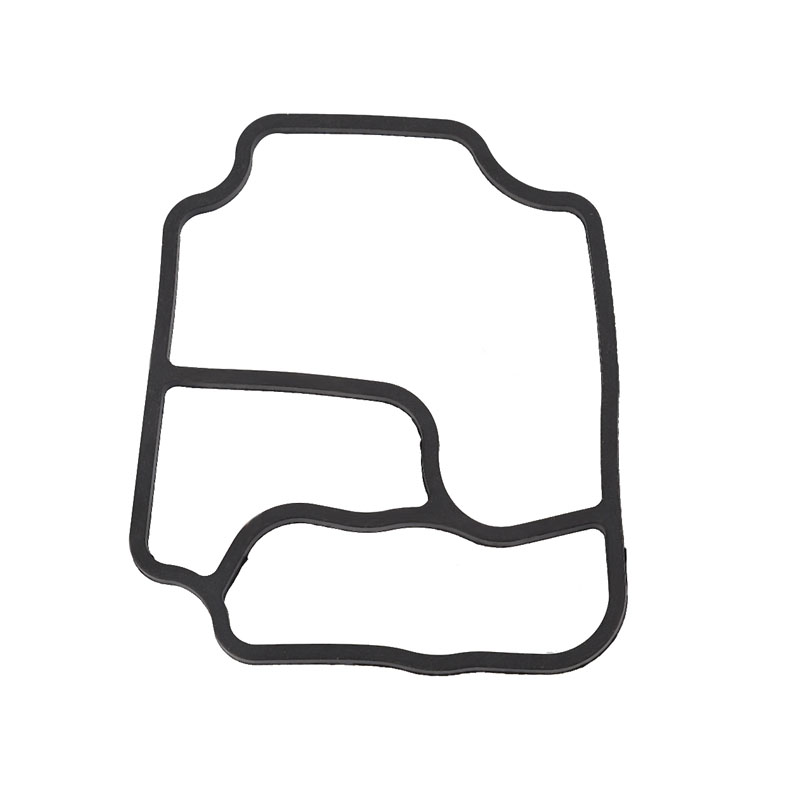

polaris front differential

Let us focus on trustworthiness, establishing a trustworthy reputation requires transparency and proficiency in dealing with Polaris front differentials. Genuine parts should be used for any replacements or repairs. Ensuring that the technicians handling the maintenance are knowledgeable about Polaris systems can significantly impact your machine’s performance and longevity. Documentation of all service records is an important part of maintaining transparency and allowing for future reference if the vehicle encounters any issues down the line. Innovative developments are continually advancing the functionality of Polaris front differentials. The incorporation of electronic control systems in newer models enhances precision handling, allowing for seamless transition between different traction settings. These advancements make the machines incredibly versatile, handling everything from soft ground conditions to rocky surfaces with equal ease. Staying abreast of new technology and upgrades can provide an edge to your vehicle’s performance and enhance user safety. To tap into your personal experience with your Polaris front differential, consider sharing user insights with the broader community. Many product forums and user groups offer a wealth of knowledge and real-world solutions to enhance your experience. These platforms can also provide insight into common issues faced by other users and the practical solutions they have implemented, empowering you to troubleshoot minor problems independently. Finally, while Polaris front differentials are designed for robustness and outstanding performance, the user’s level of care and maintenance can not only preserve but enhance this functionality. By understanding the mechanics involved, adhering to scheduled maintenance, using authentic parts, and staying informed about technological advancements, you ensure that your vehicle performs at its utmost capability, providing a reliable and exhilarating off-road experience. Taking these steps establishes a strong foundation for both the driver and the vehicle, fostering a dependable relationship between man and machine.

-

Seal 12x20x5: Precision Radial Shaft Seals for Industrial Reliability

News Nov.24,2025

-

Seal 12x18x5: Essential Guide to Specifications, Applications & Vendors

News Nov.24,2025

-

Understanding Seal 12 20 5: Applications, Specifications & Industry Insights

News Nov.23,2025

-

Durable Oil Seal 85x110x12 – Reliable Sealing Solutions for Industry

News Nov.23,2025

-

Durable and Precise Oil Seal 75x95x10 for Efficient Machinery | YJM Seal

News Nov.22,2025

-

Durable Oil Seal 75x100x10 for Reliable Industrial Performance | YJM Seal

News Nov.22,2025

-

High-Quality Oil Seal 65x90x10 | Durable & Reliable Sealing Solutions

News Nov.22,2025

Products categories