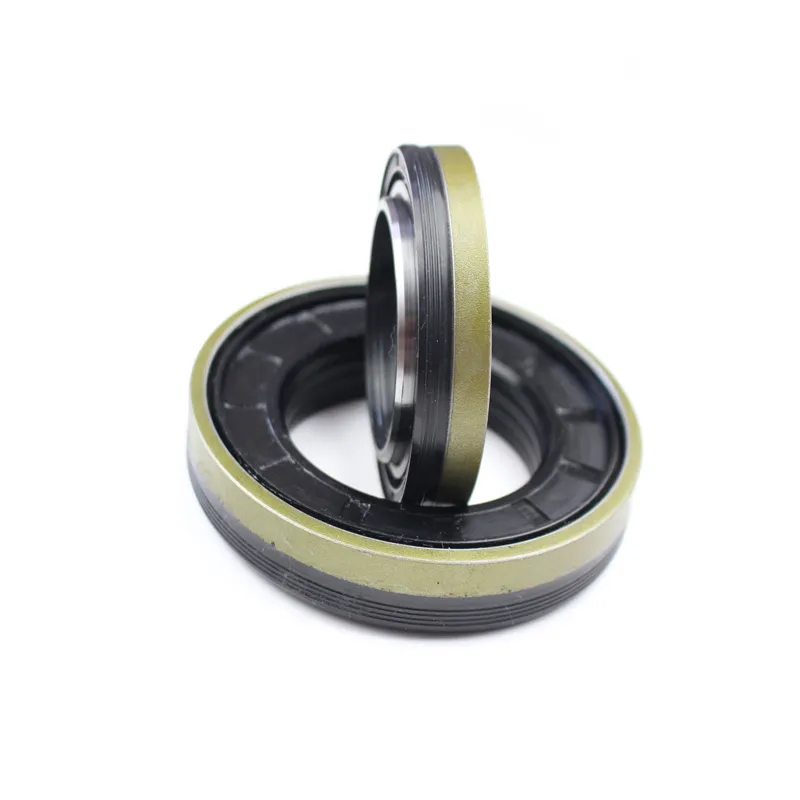

oil seal 100x130x12

Moreover, the credibility of the supplier for these seals cannot be overstated. Industries often opt for established suppliers with certified components, guaranteeing compatibility and durability. A reputable supplier not only boosts trust but also provides extensive support including technical advice and after-sales service. A case study involving a manufacturing plant demonstrated reduced operational costs and increased trust in their processes after switching to a supplier renowned for their rigorous quality control and reliable oil seals of the 100x130x12 dimensions. In terms of SEO optimization and authority in this sector, online resources and communities such as engineering forums and industrial blogs frequently discuss and review oil seals based on real user experiences. These platforms serve as valuable repositories of collective wisdom. Joining such communities can significantly enhance knowledge and keep businesses updated on technological advancements that may impact oil seal performance and selection criteria. Future challenges and innovations in oil seals also revolve around sustainability and efficiency. There is ongoing research aimed at developing seals with reduced friction coefficients and longer life spans, contributing to energy savings and lower emissions in industrial applications. Innovative designs and materials such as polytetrafluoroethylene (PTFE) composites are being explored to provide enhanced performance under extreme conditions. Oil seals like the 100x130x12 are more than mere components; they are integral to the health and efficiency of machinery across various sectors. Understanding their function, installation, and maintenance through expert insights ensures the longevity and reliability of the equipment they serve. Through careful selection, trusting community recommendations, and maintaining good practices, industries can optimize operations and reduce the likelihood of costly breakdowns.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories