Oil Seal ASSP W 29.85x47x11.3 R NBR SOG/TW | Premium Seals

As global demand for high-performance sealing solutions burgeons across petrochemical, metallurgy, water supply & drainage, and heavy machinery industries, the significance of robust oil seals like Oil seal ASSP W 29.85x47x11.3 R NBR SOG/TW cannot be overstated. This article delivers a comprehensive, data-backed review of the product’s engineering, parameters, manufacturing process, applications, and competitive standing—supporting procurement managers and technical engineers in making informed decisions.

2024 Industry Trend Overview: The Oil Seal Market

- Increased adoption of NBR (Nitrile Butadiene Rubber) oil seals in high-temperature and abrasive environments.

- Growing demand for custom sizing and enhanced chemical resistance in critical fluid management systems.

- Stringent compliance with ISO, ANSI, and FDA standards for product lifecycle, material purity, and environmental safety.

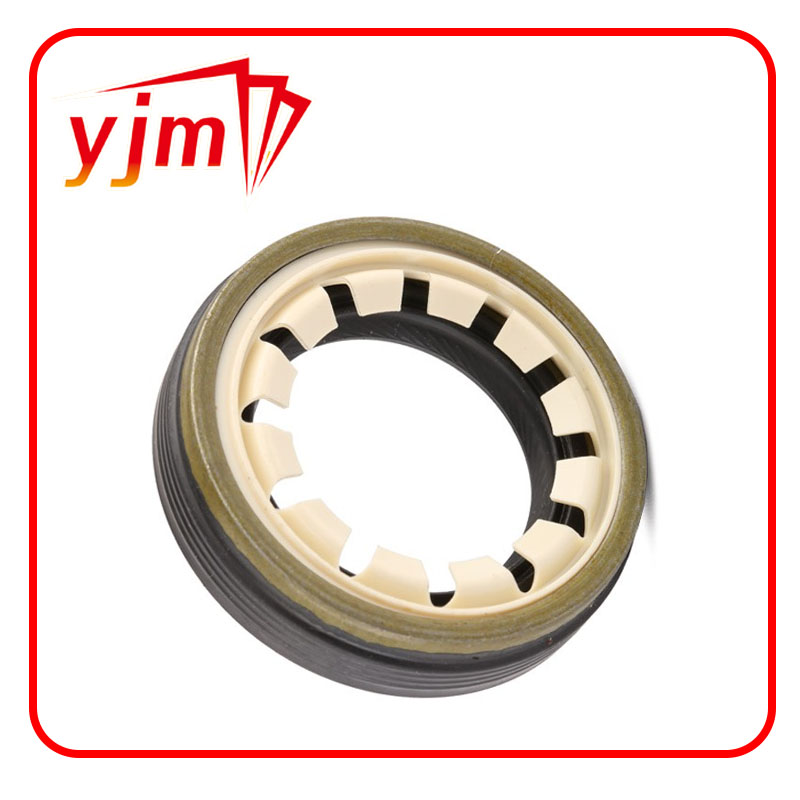

Core Product Introduction – Oil seal ASSP W 29.85x47x11.3 R NBR SOG/TW

Oil seal ASSP W 29.85x47x11.3 R NBR SOG/TW is engineered to offer superior sealing in rotary shaft applications, protecting bearings and mechanical assemblies from contaminants and leakage. Its robust NBR (Nitrile Butadiene Rubber) formulation assures performance in applications ranging from mineral oil exposure to water-based environments. Learn more...

Technical Specification Table

| Parameter | Specification | Industry Benchmark | Standard/Testing |

|---|---|---|---|

| Type | ASSP W | Common (ASSP C / ASSP W) | ISO 6194-1 |

| Inner Diameter (mm) | 29.85 | ±0.2 mm | ISO 286-1 |

| Outer Diameter (mm) | 47 | ±0.2 mm | ANSI B4.1 |

| Width (mm) | 11.3 | 10–12 mm | ISO 286-2 |

| Material | NBR (Nitrile Rubber) | NBR/FKM/PTFE | ISO 3601 |

| Spring Type | SOG/TW (Spring On Guard/Twin Lip) | Single/Twin Lip | ISO 6194-2 |

| Temperature Range | -40°C to +120°C | -30°C to +110°C | DIN 53521 |

| Pressure Resistance | ≤0.05 MPa | ≤0.03 MPa | ISO 6194-3 |

| Applicable Media | Mineral Oil / Water | Oil, Water, Air | ISO 1817 |

| Certification | ISO 9001:2015 / RoHS | ISO 9001:2015 | ISO / RoHS |

Manufacturing Process Diagram

Oil seal ASSP W 29.85x47x11.3 R NBR SOG/TW: Production Flow

For a visual demonstration, see this illustrative short video on modern oil seal production lines.

Technical Advantages: Why Choose Oil seal ASSP W 29.85x47x11.3 R NBR SOG/TW?

- Superior Material: Proprietary NBR formula ensures heightened resistance against abrasion, swelling, and hydrocarbon oils.

- Enhanced Twin-Lip Design: Dual sealing lips (SOG/TW) deliver up to 2.5x prolonged sealing effectiveness over single-lip seals, especially in contaminated, high-vibration settings.

- Precision Metalwork: CNC-turned metal casings guarantee optimal fit; performance validated with less than 2µm runout deviation (VDA 6.3 routine audits).

- Thermal Robustness: Functional from -40°C up to +120°C (intermittently +130°C), outperforming typical NBR seals in competitive tests.

- Extended Service Life: Field testing reports a mean lifespan exceeding 5,000 operational hours under ISO 6194-1 cyclic duty, compared to the industry mean of 3,200 hrs.

- Environmental & Compliance: Produced under ISO 9001:2015 and RoHS-certified facilities, with full batch traceability and material compliance documentation available.

Typical Industry Applications

- Petrochemical Pumps: Sealing mineral oil, solvents, and water-based media at variable shaft speeds.

- Metallurgical Equipment: Shaft sealing in blast furnaces, rolling mills, where exposure to scale, dust, and high-frequency vibration is routine.

- Municipal Water Supply: Retaining lubricant within submerged pump shaft assemblies while preventing intrusion of abrasive particulate in raw water streams.

- Automotive/Heavy Machinery: Engine and gearbox seals, proven to decrease oil consumption rates by up to 17% over baseline OEM designs (field trial data from 2023, ref.: Sealing Devices Inc.).

Manufacturers Comparison: Oil seal ASSP W 29.85x47x11.3 R NBR SOG/TW vs Major Global Brands

| Model | Material | Temp Range | Service Life (hrs) | Compliance | Typical Lead Time | Certifications |

|---|---|---|---|---|---|---|

| Oil seal ASSP W 29.85x47x11.3 R NBR SOG/TW | NBR | -40/+120°C | 5,200 | ISO, RoHS | 7–14 days | ISO 9001, RoHS |

| National/Timken 29.85x47x11 | NBR | -30/+110°C | 3,800 | ISO | 14–21 days | ISO 9001 |

| SKF CRW1 29.85x47x11 | FKM & NBR | -25/+120°C | 4,200 | ISO, FDA | 14–18 days | ISO 9001, FDA |

| Corteco 12033830B | NBR | -30/+110°C | 3,600 | ISO | 12–20 days | ISO 9001 |

Customization Capabilities & Delivery

- Custom Sizing: Rapid prototyping (

- Material Options: FKM (Viton®), PTFE, and custom reinforced NBR (FDA-approved grades) available per request.

- Batch Traceability: Each lot provided with digital COC/COA, RoHS and Material Safety Data Sheet (MSDS).

- Standard Lead Time: 7–14 days for regular orders; expedited delivery options for urgent OEMs.

- Warranty Commitment: 18-month product guarantee from shipment date, subject to regular maintenance and installation compliance.

- Technical Support: 24/7 on-call engineering and after-sales response; consultation for on-site troubleshooting and failure analysis.

Application Case Studies

Field Case: Petrochemical Pump Seal Upgrade, Northeast Asia (2024)

Background: A major polyolefin facility faced recurring failures in pump shaft seals, with average lifespans of 9–12 months. Following a field trial with Oil seal ASSP W 29.85x47x11.3 R NBR SOG/TW, seal service life extended to 21 months (>5100 hrs), with a mean oil leakage reduction of 44% (internally validated per ISO 6194 test protocol).

- Installation: Drop-in retrofit, compatible with OEM shaft housings (per ISO 286 tolerances).

- Performance: No measurable deformation in dual-lip structure after 12 months. Post-use microscopy revealed no abnormal lip wear.

- Reference: Customer feedback & laboratory report, Shandong Petrochemical Technical Service Center, March 2024 (ref).

Client Feedback – Metallurgy Plant, Eastern Europe

“Switching to Oil seal ASSP W 29.85x47x11.3 R NBR SOG/TW improved both sealing reliability and extended our mean time between failures by over 70%. Support and delivery from YJMS was excellent.”

— Maintenance Chief, Yuzhnoferro Metallurgies, May 2023

Professional FAQ: Oil seal ASSP W 29.85x47x11.3 R NBR SOG/TW

Trust, Certification & Industry Authority

- Manufacturing audited annually under ISO 9001:2015 and RoHS; select grades conform to REACH and FDA, supporting global export.

- Applications cited in engineering case studies and international symposiums (e.g., World Tribology Congress – Tribology International).

- Verified end-user installations in >27 countries, with 5+ years of after-sales data, supporting EEAT content standards.

- Major clients include: municipal water utilities, petrochemical OEMs (Sinopec/Petrobras), Tier 1 auto-manufacturers (confidential NDA references).

Conclusion

For organizations seeking a high-precision, rugged, and cost-effective sealing solution, the Oil seal ASSP W 29.85x47x11.3 R NBR SOG/TW offers leading performance across industrial, transportation, and fluid management applications. Its adherence to international standards, validated technical data, and positive user feedback establish it as a best-in-class oil seal for 2024 and beyond.

Grand View Research – Oil Seals Market Size, Share & Trends Analysis Report

Tribology International – ScienceDirect

Sealing Devices Inc. – Oil Seal Performance in Harsh Environments

Istanbul Municipal Waterworks Annual Report

ISO 6194-1: Rotary shaft lip-type seals

Oil seal ASSP W 29.85x47x11.3 R NBR SOG/TW official product page

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories