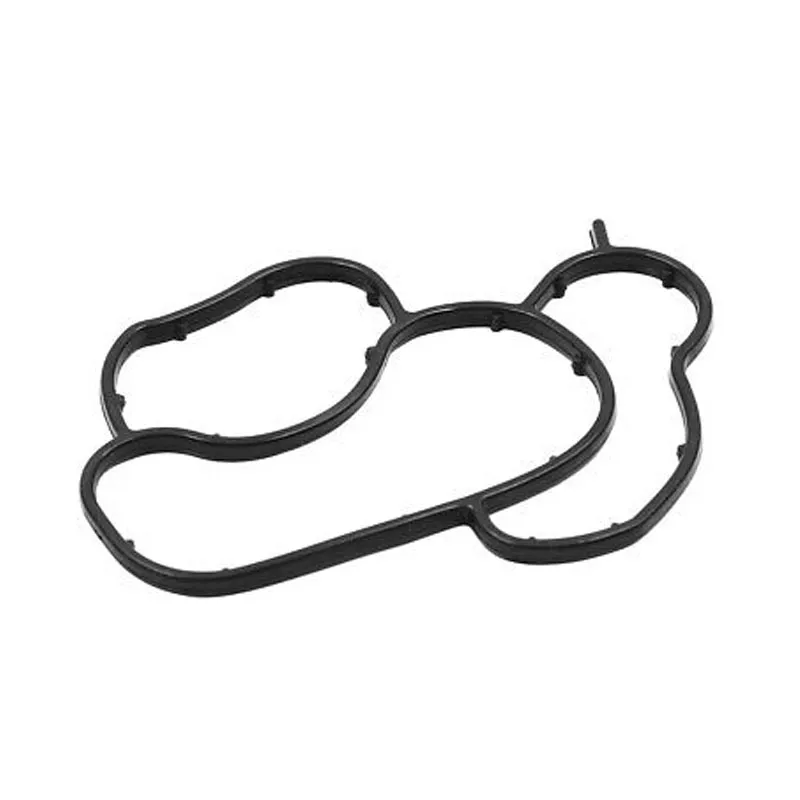

Engine Crankshaft Oil Seal 9031683001

A common mistake in oil seal installation is improper alignment. Ensuring that the seal is aligned perfectly is paramount to avoid uneven pressure and accelerated wear. Utilizing installation tools like seal drivers or presses enhances precision and maintains consistency across installations, thereby establishing trust in the repeatability of the process. An expert installer is aware of the importance of carefully guiding the seal into its seating without applying excessive force that could deform the seal or the shaft. After installation, conducting thorough testing is a hallmark of authoritative practice. This involves running the machinery under controlled conditions to observe the oil seal’s performance. Monitoring for leaks, noise, and unusual vibrations can provide immediate insights into installation success. Additionally, incorporating sensors or gauges can extend the monitoring capability, alerting to changes in pressure or temperature that might signify seal failure. Finally, documentation is critical. Recording the installation procedure, tools used, and any observations during testing can significantly boost trustworthiness. This documentation not only serves maintenance schedules but also provides a reference for future installations, highlighting any procedural improvement areas or common issues. In conclusion, mastering the art of oil seal installation requires a blend of experience, expertise, meticulousness, and a commitment to following manufacturer guidelines. By adhering to these principles, one can ensure machinery operates efficiently and reliably, maximizing both performance and lifespan. A trusted source of information and skill, this guide stands to empower professionals in achieving excellence with each oil seal installation.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories