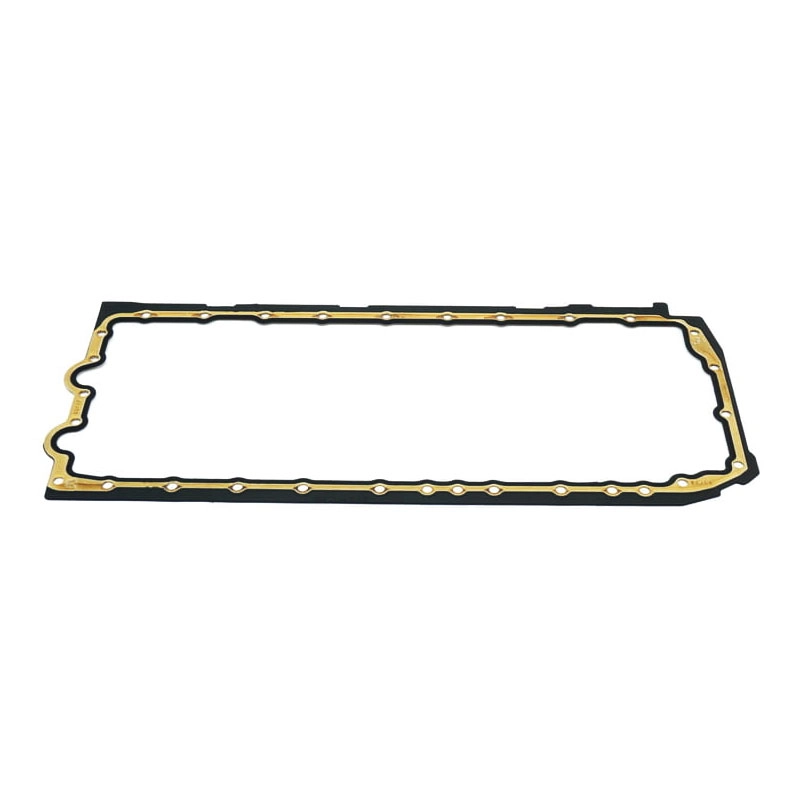

OEM Oil Drain Plug Gaskets Washer 11026 01M02 for Nissan Qashqai Teana Livina

From an automotive engineering perspective, the precision of a drain crush washer's design cannot be ignored. Each washer is crafted to exacting standards, matching specific torque settings. Modern engines have very tight tolerances, and the correct application of torque is what enables these washers to perform effectively. Under-torquing can result in leaks due to insufficient crushing, while over-torquing might damage the washer or the plug threads, indirectly affecting the sealing capability. For environmentally-conscious vehicle owners, the proper disposal of used drain crush washers is worth noting. Although small, these components should be recycled correctly due to the metals involved. Some auto parts retailers offer recycling programs or disposal guidelines, allowing responsible disposal with minimal environmental impact. Authoritative automotive sources and experienced car enthusiasts alike emphasize the drain crush washer's role in preventive vehicle maintenance. Recognizing the economic implications of neglecting this small part is key to understanding its importance. A minor investment in new washers at each oil change can save substantial repair costs, offering peace of mind and ensuring the vehicle's longevity. In summary, the drain crush washer is a simple yet profoundly effective piece of the automotive maintenance puzzle. Its role in sealing the drain plug securely makes it indispensable for maintaining engine integrity and efficiency. For those seeking to uphold the highest standards of vehicle care and performance, respecting the necessity of fresh, quality crush washers is a small but critical part of the commitment to excellence.

-

Understanding Flat Gaskets: Types, Materials, and Industrial Applications

News Jul.25,2025

-

Understanding Bonded Seals: Types, Applications, and Industrial Advantages

News Jul.25,2025

-

The Complete Guide to Flat Gaskets: Materials, Uses, and Applications

News Jul.25,2025

-

Sealing Solutions: A Comprehensive Guide to Flat Ring Gaskets and Seals

News Jul.25,2025

-

Flat Gaskets Explained: Materials, Applications, and Best Uses

News Jul.25,2025

-

Everything You Need to Know About Automotive Drain Plugs and Oil Pan Maintenance

News Jul.25,2025

-

Understanding Oil Drain Plugs: Quick, Universal, and Self-Tapping Options for Every Engine

News Jul.24,2025

Products categories