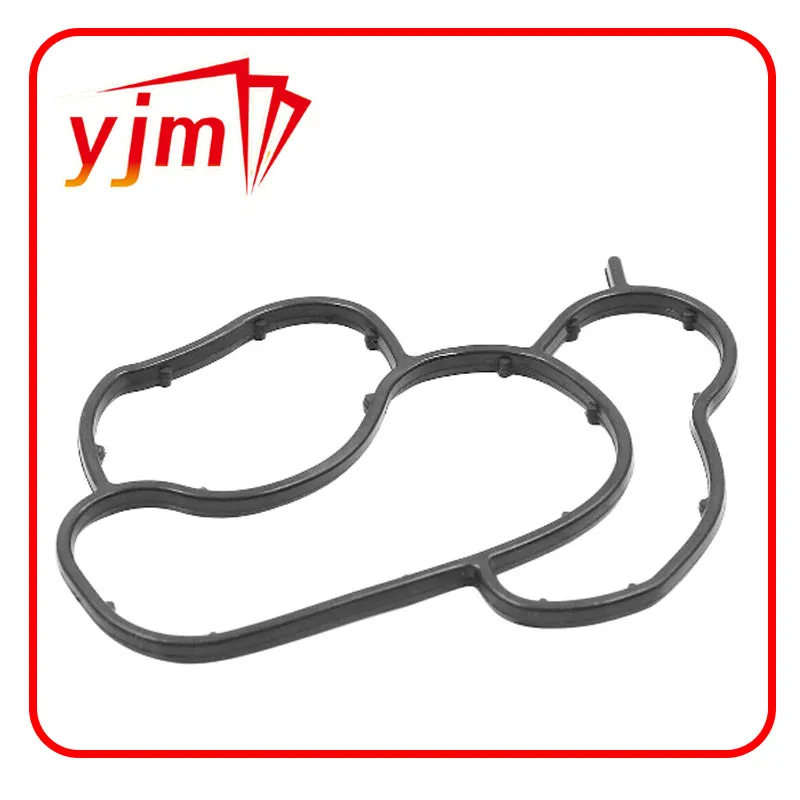

series 60 oil pan gasket

For those responsible for maintaining vehicle fleets, investing in quality gaskets can lead to long-term savings. Cheaper alternatives might cut immediate costs but often at the expense of durability, leading to more frequent replacements and the potential for engine damage over time. Relying on reputable suppliers who provide OEM (Original Equipment Manufacturer) or high-quality aftermarket gaskets is a wise choice, as it aligns with best practice maintenance standards. In terms of authority and trustworthiness, referring to service manuals from the engine manufacturer is crucial, as these documents provide tried and tested information crucial for maintaining engine health. Additionally, engaging with a professional community, either through forums, webinars, or workshops, can provide insights into the latest advancements and techniques related to Series 60 engine maintenance. Real-world experience from seasoned mechanics often highlights recurring issues that could arise. For example, a slightly bent oil pan flange can quickly compromise the new gasket, a problem that can be overlooked if not experienced in handling Series 60 engines. Furthermore, regular inspections can preemptively catch wear or distortions in the gasket, allowing for timely replacements before any significant issues arise. Ultimately, the Series 60 oil pan gasket is more than just a simple component; it's a critical aspect of engine maintenance that ensures the vehicle runs optimally. With the right combination of quality materials, expert installation, and regular inspection, it provides peace of mind and prolongs the life of a valuable asset. Understanding its importance in engine management underscores a proactive approach to vehicle maintenance that is grounded in both expertise and experience, ultimately fortifying trust among clients and owners.

-

Understanding Flat Gaskets: Types, Materials, and Industrial Applications

News Jul.25,2025

-

Understanding Bonded Seals: Types, Applications, and Industrial Advantages

News Jul.25,2025

-

The Complete Guide to Flat Gaskets: Materials, Uses, and Applications

News Jul.25,2025

-

Sealing Solutions: A Comprehensive Guide to Flat Ring Gaskets and Seals

News Jul.25,2025

-

Flat Gaskets Explained: Materials, Applications, and Best Uses

News Jul.25,2025

-

Everything You Need to Know About Automotive Drain Plugs and Oil Pan Maintenance

News Jul.25,2025

-

Understanding Oil Drain Plugs: Quick, Universal, and Self-Tapping Options for Every Engine

News Jul.24,2025

Products categories