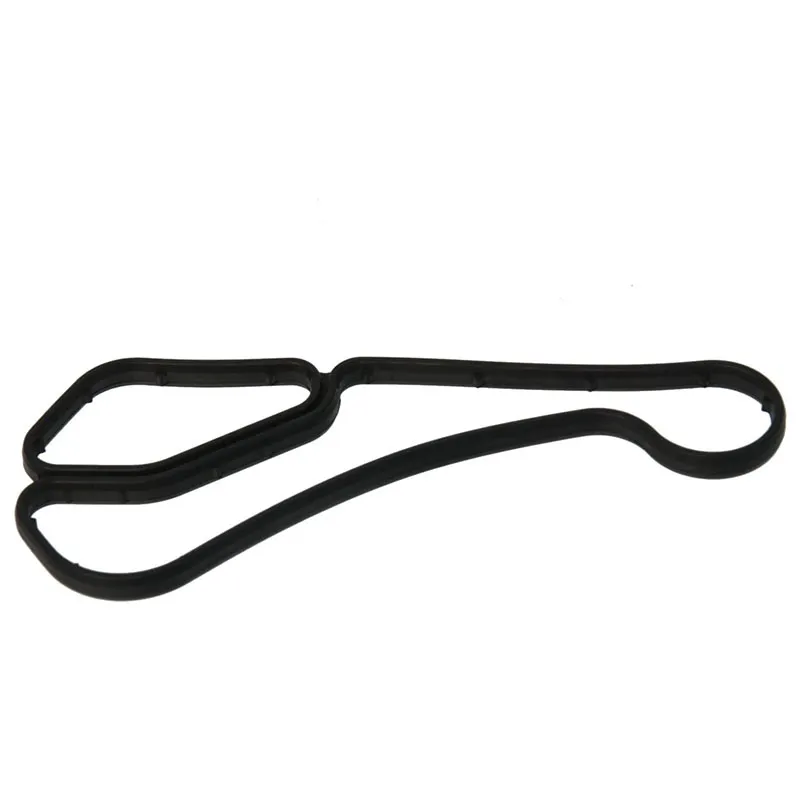

heavy duty rubber seal

Trustworthiness is further reinforced through rigorous testing procedures that these seals undergo before deployment. From compression set evaluations to tests for tensile strength and elongation, these seals are meticulously examined to ensure they surpass the stringent criteria set forth by regulatory bodies. Such diligence reassures clients of a product's reliability when subjected to the harshest environments. Additionally, utilizing heavy-duty rubber seals offers environmental benefits. By ensuring a secure seal that minimizes leaks and emissions, these robust solutions contribute to sustainable industrial practices. Operations that adopt these seals often see tangible reductions in wastage and spillage, aligning with global sustainability trends and responsibly addressing ecological concerns. From a practical standpoint, businesses experience marked improvements in productivity when heavy-duty rubber seals are integrated into their systems. Equipment uptime increases as these durable seals mitigate frequent failures and malfunctions, enabling smoother workflow without the interruptions caused by seal repairs or replacements. In conclusion, heavy-duty rubber seals represent a fusion of expertise, innovation, and reliability. Their role as an indispensable component within diverse sectors highlights the crucial intersection of performance excellence and environmental stewardship. With a focus on customization and rigorous quality standards, these seals not only stand up to the most challenging conditions but also provide a foundation of trust and authority within the industrial landscape. Embracing heavy-duty rubber seals is not merely a purchase decision but a strategic move towards operational efficiency and sustainability in the age of industrial precision.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories