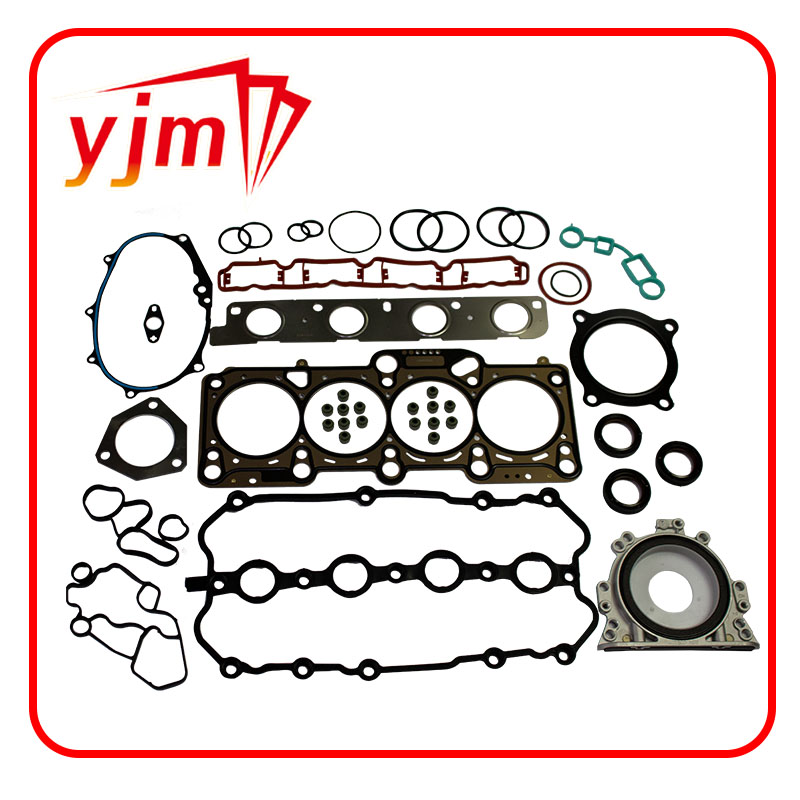

25x35x7 oil seal

Authoritative advice from industry professionals emphasizes the importance of proper installation. Even the finest oil seal can fail if not installed correctly. Ensuring that the seal is seated without distortion and maintaining the cleanliness of mating surfaces are best practices vital for achieving optimal performance. This attention to detail during installation reflects the trustworthiness and reliability associated with the correct use of a 25x35x7 oil seal. Furthermore, advancements in sealing technologies have led to innovations such as double-lip designs in these seals, providing extra protection against invasive contaminants while safeguarding internal lubrication. These innovative solutions demonstrate the dynamic nature of oil seal technology, continually evolving to meet the demands of high-performance and precision engineering environments. When selecting a 25x35x7 oil seal for specific applications, consider consulting with experts who can provide insights tailored to your machinery's requirements. Professional assessments often include reviewing factors such as shaft surface speed, temperature, and pressure conditions, as well as environmental exposures, to recommend the most suitable sealing solution. This ensures not only the longevity of the seal but also the optimal performance of the machinery in which it is employed. In summary, with its precise dimensions, robust material selection, and innovative designs, the 25x35x7 oil seal represents a trustworthy component in the arsenal of any engineer or mechanic. Embracing this component's capabilities by leveraging expert knowledge and installation precision can profoundly impact the efficiency and reliability of your machinery, ultimately contributing to smoother operations and enhanced productivity.

-

Understanding Oil Crush Washers: A Small Component with a Big Role in Vehicle Maintenance

News Jun.19,2025

-

The Essential Guide to Sump Plug Washers: Types, Sizes, and Why They Matter

News Jun.19,2025

-

Plastic Oil Drain Plugs: What You Need to Know Before Your Next Oil Change

News Jun.19,2025

-

Mastering Oil Drain Plug Maintenance: From Stripped Bolts to Smart Replacements

News Jun.19,2025

-

Do You Really Need a New Oil Washer Every Time? A Guide to Crush Washers and Oil Drain Plug Seals

News Jun.19,2025

-

A Modern Guide to Oil Drain Plugs: From Quick Valves to Thread Repairs

News Jun.19,2025

-

Versatile Sealing Solutions: Understanding the Power of the Seal Ring and O Ring

News Jun.18,2025

Products categories