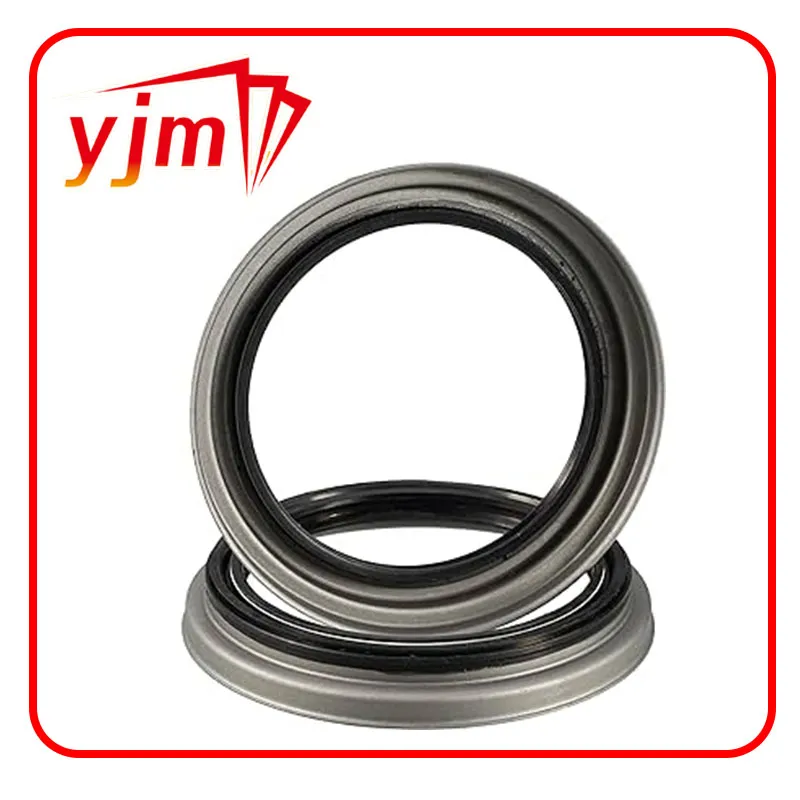

chemical resistant o rings

Beyond technical specifications, square cut O-rings offer an advantage in customization. Companies can tailor their design to meet specific operational criteria, which is particularly useful in innovative manufacturing processes where standard parts may not provide the necessary fit or function. This level of customization extends to both the dimensions and the choice of materials, enabling companies to precisely address their unique operational challenges. The square cut O-ring market has witnessed innovation, with manufacturers investing in improving the material blends and production processes to enhance their performance further. Notable advancements include improving the thermal stability of materials, reducing production costs, and enhancing the precision of the cutting process to ensure tighter tolerances. These efforts reflect the industry’s acknowledgment of square cut O-rings as a reliable solution for modern engineering challenges. When considering the adoption of square cut O-rings, it is essential to partner with reputable suppliers who emphasize quality and compliance with industrial standards. A focus on quality assurance ensures that the products delivered are reliable and trustworthy, maintaining the integrity of the systems in which they are installed. Reliable suppliers often offer technical support and consultation services, aiding in the correct selection and implementation of the product, thus further instilling confidence and ensuring a successful application. In conclusion, square cut O-rings offer a unique solution for high-demand sealing applications, backed by their superior design and material adaptability. Their rise in popularity is a testament to their effectiveness, providing enhanced sealing capabilities and reliability that modern industries demand. As a result, they have carved a niche in the sealing solutions market, becoming an indispensable component for engineers and manufacturers alike seeking to enhance performance and safety in their operations.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories