high temp o rings

In the automotive sector, high temperature O-rings find their relevance in engine systems where they handle hot fluids and gases. Their ability to maintain elasticity and resilience ensures that they provide a continuous seal without hardening or cracking over time, thus preventing leaks that could lead to catastrophic engine failures. Such reliability comes from years of dedicated research and development, spearheaded by trusted manufacturers who have become authorities in the field. From an experience perspective, field tests and real-world applications have consistently validated the performance of high temperature O-rings. Maintenance teams in power plants, for instance, have reported increased operational time and reduced maintenance costs by integrating high temperature O-rings in boiler systems and steam applications. These real-world endorsements serve as a testament to the trustworthiness of these components. The trustworthiness of high temperature O-rings is further supported by rigorous quality control and certification standards that manufacturers adhere to. These include ISO certifications and stringent testing procedures that assess performance under simulated real-world conditions. Such standards ensure that every O-ring delivered is capable of meeting or exceeding the specifications required for demanding applications. As industries evolve and the demand for high-performance solutions grows, the role of high temperature O-rings continues to expand. They offer a reliable solution that addresses both present-day needs and anticipates future challenges, backed by ongoing innovation and a commitment to excellence from manufacturers. In summary, when efficiency, safety, and reliability are paramount, high temperature O-rings stand out as a critical component you can trust.

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

-

The Importance of Heavy Duty Seals in Industrial and Residential Applications

News Jul.30,2025

-

Exploring Industrial Oil Seals: From Felt Oil Seals to TTO and CFW Solutions

News Jul.30,2025

-

Essential Guide to Oil Seals: From Radial to Metal-Cased Seals for Industrial Reliability

News Jul.30,2025

-

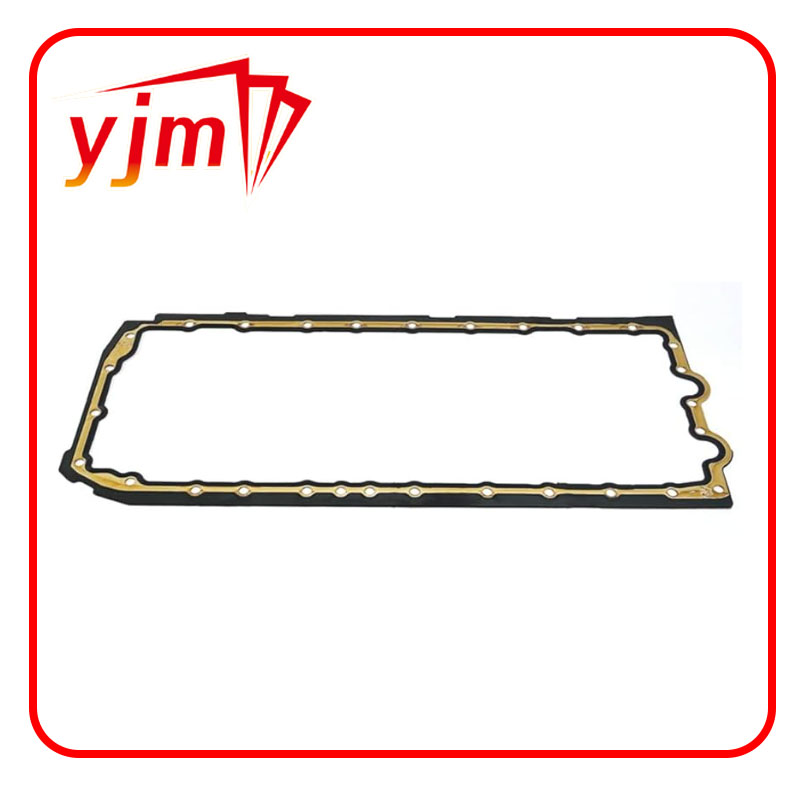

Choosing the Right Oil Seals and Gaskets for Industrial and Automotive Applications

News Jul.30,2025

-

Cassette Seals: Durable Sealing Solutions for Harsh Environments

News Jul.30,2025

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

Products categories