fuel water separator drain plug

4. Temperature and Pressure Tolerance Select a drain plug that can withstand the extremes of temperature and pressure typical of the specific environment and application. Manufacturers usually provide this information, aligning with standardized testing procedures to ensure compliance. Meeting Authoritativeness and Trustworthiness in Product Information Authoritative resources advocate for regular inspections and replacements based on usage conditions and intervals. Trusted manufacturers provide detailed specifications and certifications, ensuring each component adheres to industry standards, such as SAE (Society of Automotive Engineers) and ISO (International Organization for Standardization). Maintenance Practices and Their Importance Proper maintenance of the water separator drain plug extends the lifespan of the separator unit and enhances its efficacy. Consider the following expert-recommended practices - Regular Inspection Periodically check for signs of wear or damage. Look for cracks, worn seals, or corrosion. - Routine Cleaning Residue build-up can compromise seal efficiency. Clean the plug periodically with appropriate solvents that do not degrade its material. - Seal Replacement If the seal exhibits degradation, replace it promptly to prevent leakage. - System Flushing Occasionally flush the entire water separator system to remove accumulated contaminants. Adopting these maintenance practices not only improves system reliability but also ensures compliance with warranty requirements outlined by trusted product manufacturers. Enhancing System Performance and Reliability A well-maintained water separator with a properly functioning drain plug ensures optimal performance by preventing water contamination in fuel systems. This is crucial for maintaining efficient combustion in engines, thus reducing emissions and enhancing fuel economy. In hydraulics, it ensures consistent fluid viscosity, preventing pump and valve damage. Conclusion In summary, the water separator drain plug is an essential component in precision fluid management. Selecting the right plug and adhering to recommended maintenance practices enhance system reliability and performance. By understanding the nuanced requirements of your applications and relying on expert advice, you can ensure that your systems operate efficiently, safeguarding both equipment and environmental standards.

-

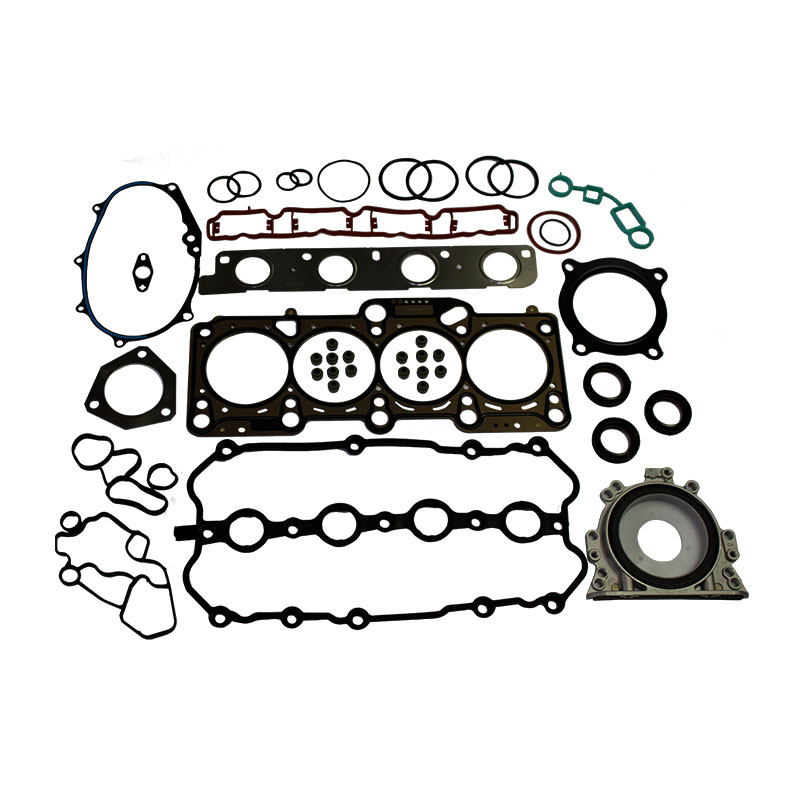

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

-

How to Identify and Fix Oil Filter Mount and Housing Gasket Leaks

News Jul.28,2025

-

Fixing Oil Housing Gasket Leaks: A Guide to Replacing Your Oil Filter Housing and Gaskets

News Jul.28,2025

-

Everything You Need to Know About Changing Your Oil Filter Housing Gasket and Related Gaskets

News Jul.28,2025

-

Essential Kits and Tools for Engine Repair and Enhancement

News Jul.28,2025

-

Diagnosing and Fixing a Leaking Oil Filter Housing Gasket: What You Need to Know

News Jul.28,2025

-

Understanding Flat Gaskets: Types, Materials, and Industrial Applications

News Jul.25,2025

Products categories