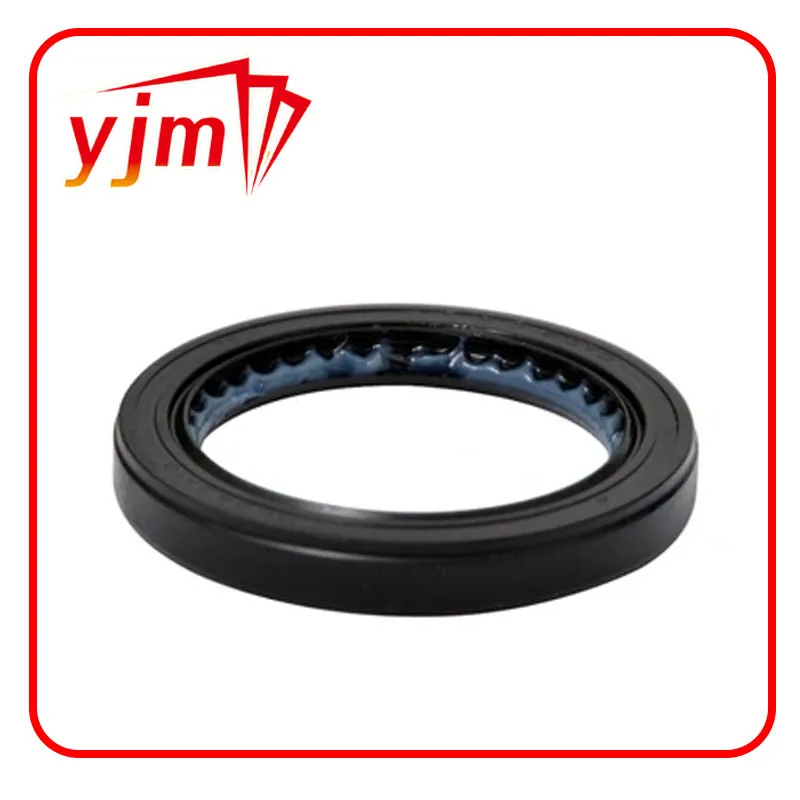

Engine Crankshaft Oil Seal 9031683001

Operational experience with 25x41 25x6 oil seals further underscores their criticality. Users report the seals' exceptional durability and resistance to deformation under pressure, which contributes to less frequent maintenance cycles and lower operational costs. As part of regular maintenance routines, professionals recommend regular inspection and timely replacement of these seals to prevent equipment malfunctions. From an expertise standpoint, selecting the appropriate oil seal configuration requires an understanding of the operational environment. Factors such as temperature range, pressure specifications, and exposure to chemicals must be considered. Collaborating with suppliers who possess detailed knowledge and experience in seal technology ensures not only the procurement of high-quality 25x41 25x6 oil seals but also their effective implementation in machinery setups. The authoritativeness of using 25x41 25x6 oil seals is bolstered by robust standards established within the engineering sector. Organizations such as ISO and the Society of Automotive Engineers prescribe stringent guidelines for their manufacturing and application, ensuring that seals meet high-performance benchmarks and are reliable under various industrial conditions. Trustworthiness of oil seal performance is ultimately a consequence of manufacturing precision, material innovation, and adherence to rigorous standards. Purchasing seals from reputed manufacturers known for their commitment to quality assurance provides peace of mind and confidence in their operational viability. In conclusion, the 25x41 25x6 oil seal embodies the quintessence of reliability and efficiency in mechanical engineering. Its careful design, material resilience, and compliance with industry standards underscore its essential role in maintaining operational integrity. By investing in such critical components, industries pledge to uphold performance, safety, and sustainability in their machinery systems. As technology advances, the ongoing evolution in oil seal materials and designs promises even greater efficiencies and protections against the challenges of modern engineering environments.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories