ボンデッドシールの特性

.ldeal 圧力ガスケット

.Reliable sealing at high & low pressure High & low temperature capability

.Reduced bolt torque with no loss of tightening loads Metal ring prevents rubber compression

金属リングがゴムの圧縮を防ぎます

ボンデッドシールは、以下を含むさまざまな素材から選択できます。

.Mild Steel . Nitrile -30 °C to +100 °C

.Mild Steel . HNBR -20 °C to +150 °C

.Stainless Steel .Viton -20 °C to +200°C

.Brass .EPDM - 50 °℃ to +150°C

.Aluminium .Silicone -60°C to +250°C

We can supply Bonded Seals in both standard and Self-Centering styles to in the following ranges: Metric "Inch *BSP ,German Metric *French Metric

製品詳細

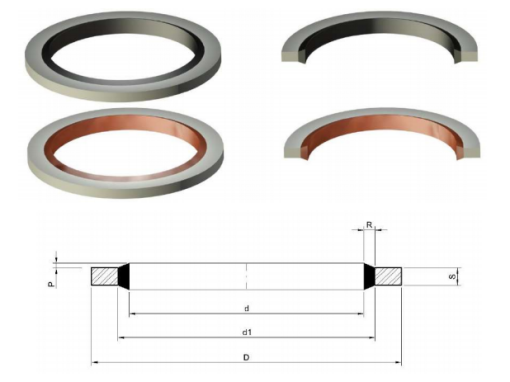

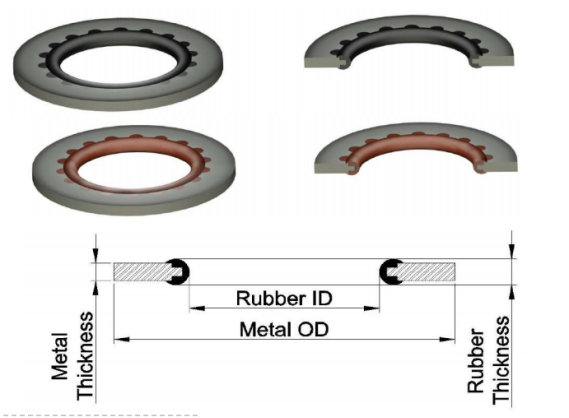

GM500/WX/US/USIT 1

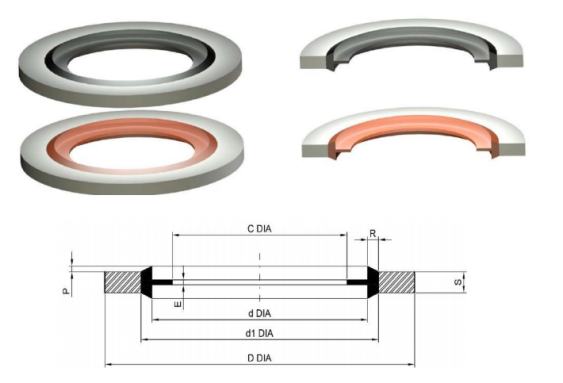

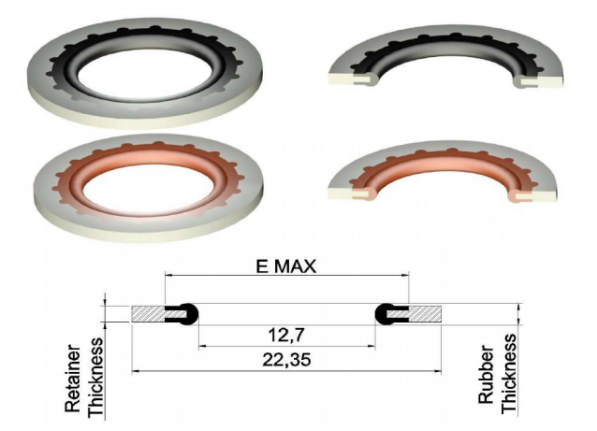

GM500 セルフセンタリング /WZ /USS/USIT 1 SF

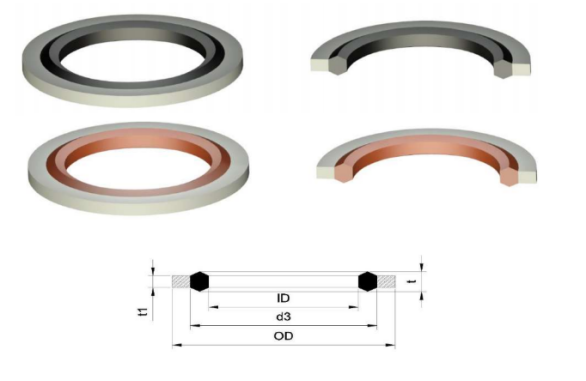

GM1000

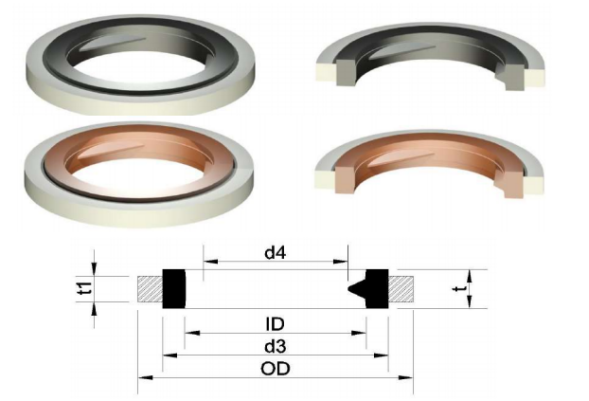

GM2000

600

610

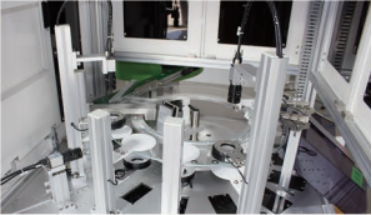

品質検査ビジョン検査自動化

There are 4 detection modules on the edge of the turntable.The detection module takes pictures and transmits them to the software system for analysis and judgment. Non-conforming products will be marked and rejected by the defective window, and qualified products will eventually be collected easily. Pass rate up to 99.5%.

What is the difference between bonded seal and dowty seal?

A bonded seal and a Dowty seal are two names often used interchangeably to describe the same type of sealing component, but there are subtle differences in terminology and usage depending on context and industry. Both are composite seals designed to provide reliable sealing under high-pressure conditions, particularly in hydraulic and pneumatic systems.

What Is a Bonded Seal?

A bonded seal is a type of washer that consists of a metal ring (usually steel or stainless steel) with a vulcanized rubber sealing element (typically nitrile rubber or FKM) bonded to its inner diameter. This combination creates a durable and reusable sealing washer capable of withstanding high pressures and temperatures. When compressed between two surfaces—such as a bolt head and a housing—the rubber element deforms to fill any gaps, creating a leak-proof seal.

What Is a Dowty Seal?

The term Dowty seal originally referred to a brand name for bonded seals developed by the British engineering company Dowty Group. Over time, “Dowty seal” has become a generic term in many industries, especially in the UK and Commonwealth countries, to describe bonded seals in general. In practice, a Dowty seal is a type of bonded seal, but not all bonded seals are Dowty seals in the strictest branding sense.

Key Differences

|

特徴 |

ボンデッドシール |

Dowty Seal |

|

Definition |

General name for metal-rubber sealing washers |

Brand-originated term for bonded seals |

|

材料 |

Metal (usually steel) + bonded rubber |

Same materials |

|

Usage Context |

Used in various industries globally |

Term often used in British/Commonwealth industries |

|

Interchangeability |

Fully interchangeable in function |

Often considered the same as bonded seal |

Applications

Both bonded and Dowty seals are widely used in:

Hydraulic fittings

Fuel systems

Oil drain plugs

High-pressure connections

Automotive and industrial machinery

While the bonded seal and Dowty seal perform the same function and have an identical structure, the difference lies mainly in naming and origin. “Dowty” is essentially a branded or colloquial term for a bonded seal, and in practical applications, they are functionally equivalent. Regardless of the name used, these seals are critical in preventing leaks in high-pressure systems and ensuring long-term mechanical integrity.

What does a bonded seal do?

A bonded seal is a highly reliable sealing device designed to provide a tight, leak-proof seal in high-pressure applications. It is composed of two main parts: a metal washer (typically made of stainless steel or carbon steel) and an elastomeric sealing ring (commonly made from materials like nitrile rubber, Viton, or silicone) that is bonded to the inner edge of the washer. The purpose of a bonded seal is to prevent fluid or gas from leaking around bolts, screws, and other fasteners in hydraulic, pneumatic, or mechanical systems.

How It Works

When a bonded seal is installed between two flat surfaces—usually where a bolt or threaded fitting is tightened—the metal washer provides structural support while the rubber insert compresses and deforms slightly. This creates a tight seal against both the mating surface and the fastener. The elasticity of the rubber compensates for minor imperfections on the sealing surfaces, ensuring a durable and leak-free connection.

Advantages of Bonded Seals

High Pressure Resistance: Bonded seals are ideal for high-pressure systems, often used in hydraulics and pneumatics.

Temperature and Chemical Resistance: Depending on the rubber material used (e.g., Viton for high temperature or chemical resistance), bonded seals can perform well under various environmental conditions.

Reusable in Some Cases: While the elastomer may degrade over time, the metal washer adds durability, and in less critical systems, the seals can sometimes be reused.

Easy to Install: Bonded seals can be quickly and easily installed without special tools, making them convenient for both OEM and maintenance applications.

Common Applications

Bonded seals are used across many industries, including:

Automotive: sealing engine bolts, oil drain plugs, and transmission parts.

Aerospace: ensuring leak-free connections in hydraulic and fuel systems.

Industrial Equipment: used in pumps, compressors, and machinery.

Hydraulic Systems: sealing between hydraulic fittings and threaded joints.

In summary, a bonded seal provides a secure and effective sealing solution for threaded components and fasteners exposed to fluids or gases. Its combination of metal strength and rubber flexibility allows it to perform reliably in demanding environments, making it an essential part of modern mechanical and hydraulic systems.

製品カテゴリー

Related News

-

24 . Nov, 2025

24 . Nov, 2025Discover the key benefits and applications of the seal 12x20x5, a durable, cost-effective radial shaft seal used worldwide in machinery, automotive, and renewable industries.

もっと... -

24 . Nov, 2025

24 . Nov, 2025Discover everything about seal 12x18x5 — from technical specs and global applications to vendors and FAQs. Ensure mechanical reliability with the right seal.

もっと... -

23 . Nov, 2025

23 . Nov, 2025Explore the essentials of seal 12 20 5, from definitions and specifications to global uses, benefits, and supplier comparisons. Discover why these seals are vital across industries.

もっと...