Advanced Sealing Technologies: Exploring PTFE Oil Seals, Polypac Seals, and High-Performance Options

Oil seals are critical components in mechanical systems, preventing leakage of lubricants and protecting components from contamination. As machinery evolves to handle higher pressures, faster speeds, and more corrosive environments, sealing technology has advanced to meet these demands. In this article, we’ll examine key types of seals, including PTFE oil seals, Polypac seals, rubber oil seals, high-pressure seals, and hub oil seals, and how they contribute to reliable, long-lasting performance across industries.

PTFE Oil Seals: Engineered for Extreme Conditions

Polytetrafluoroethylene (PTFE) oil seals often referred to as Teflon seals, are widely used in high-performance and harsh operating conditions. PTFE is a synthetic fluoropolymer with exceptional resistance to chemicals, high temperatures, and wear, making it ideal for use in demanding applications like aerospace, chemical processing, automotive, and food-grade equipment.

Benefits of PTFE Oil Seals:

Chemical Resistance: Withstands aggressive solvents, fuels, and acids.

High-Temperature Tolerance: Performs reliably in temperatures up to 250°C (482°F).

Low Friction: PTFE’s low coefficient of friction minimizes heat generation and wear.

Dry Running Capability: Operates without lubrication in some designs.

PTFE oil seals are often used in high-speed rotary applications where traditional rubber seals might fail. They're available in both lip and spring-energized configurations, offering precise sealing even in dynamic or misaligned shaft conditions.

Polypac and Rubber Oil Seals: Balancing Versatility and Value

Polypac seals are a product line of sealing systems designed to combine the best attributes of elastomers and plastics. Often used in hydraulic and pneumatic applications, these seals feature multiple lip designs, composite materials, and backup elements to withstand fluctuating pressure and dynamic motion.

Common Types of Polypac Seals:

Rod and Piston Seals: Designed for hydraulic cylinders.

Wipers and Scrapers: Keep contaminants out of sensitive components.

Rotary Shaft Seals: Handle dynamic movement under pressure.

Polypac seals often feature PTFE and polyurethane components, providing a great blend of flexibility and durability. They’re commonly seen in construction, agriculture, mining, and manufacturing environments where reliability under pressure is essential.

In contrast, the rubber oil seal remains a staple in standard industrial and automotive applications. Typically made from nitrile rubber (NBR), hydrogenated nitrile (HNBR), or fluoroelastomer (FKM/Viton), rubber oil seals are cost-effective and perform well under moderate temperature and pressure conditions.

Advantages of Rubber Oil Seals:

Wide Compatibility: Available in both metric and imperial sizes.

Affordable and Reliable: Ideal for general-purpose sealing.

Shock Absorption: Natural elasticity helps maintain a tight fit under mechanical stress.

Rubber oil seals are suitable for sealing rotating shafts, gearboxes, and engines where they prevent lubricant leakage and protect against dust and dirt.

High-Pressure and Hub Oil Seals: Built for Heavy-Duty Applications

As equipment becomes more powerful, seals must handle greater demands. High-pressure seals are specifically engineered to perform in hydraulic systems, deep-sea exploration, oil rigs, and heavy machinery where pressures can exceed 10,000 psi (690 bar).

Design Features of High-Pressure Seals:

Backup Rings: Prevent extrusion under pressure.

Multi-lip Structures: Provide redundancy and a stronger barrier against leakage.

Reinforced Materials: Typically made from reinforced PTFE, polyurethane, or engineered thermoplastics.

These seals are crucial in preventing system failure, especially in mission-critical systems like hydraulic presses, injection molding machines, and aerospace control systems.

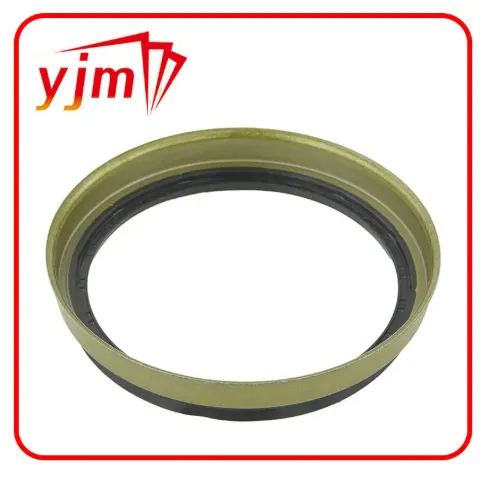

Another specialized solution is the hub oil seal, which is primarily used in wheel hubs of vehicles—especially in trucks, trailers, and heavy-duty equipment. Hub oil seals keep wheel bearings lubricated and prevent contaminants like water, mud, and dust from entering the axle system.

Features of Hub Oil Seals:

Durability: Often built with a metal casing for added protection.

Compatibility with Grease and Oil: Suitable for various lubricants.

Double Lip Options: Enhanced sealing for long-haul and off-road applications.

Proper installation and maintenance of hub oil seals are crucial, as failure can lead to axle damage, bearing failure, or hazardous leaks during vehicle operation.

Final Thoughts: Choosing the Right Seal for Optimal Performance

With a variety of oil seals available, from PTFE oil seals for high-speed chemical environments to Polypac and rubber oil seals for standard hydraulic or rotating applications, and specialized solutions like high-pressure seals and hub oil seals, choosing the right type requires careful consideration of application conditions.

When selecting a seal, consider the following:

Operating Pressure and Temperature

Chemical Compatibility

Shaft Speed and Misalignment

Lubrication and Contamination Levels

Understanding these factors will help ensure you choose a sealing solution that offers optimal performance and longevity, reducing the risk of costly failures or downtime.

-

High-Quality Seal 12x22x5 for Industrial & Automotive Use | YJM Seal

Notizia Nov.25,2025

-

Seal 12x20x5: Precision Radial Shaft Seals for Industrial Reliability

Notizia Nov.24,2025

-

Seal 12x18x5: Essential Guide to Specifications, Applications & Vendors

Notizia Nov.24,2025

-

Understanding Seal 12 20 5: Applications, Specifications & Industry Insights

Notizia Nov.23,2025

-

Durable Oil Seal 85x110x12 – Reliable Sealing Solutions for Industry

Notizia Nov.23,2025

-

Durable and Precise Oil Seal 75x95x10 for Efficient Machinery | YJM Seal

Notizia Nov.22,2025

-

Durable Oil Seal 75x100x10 for Reliable Industrial Performance | YJM Seal

Notizia Nov.22,2025

Categorie di prodotti