The Essential Guide to Oil Seals in Automotive and Industrial Applications

Oil seals are fundamental components in many mechanical systems, ensuring efficiency, durability, and cleanliness by preventing oil leakage and keeping contaminants out. From engines to wheel assemblies, different types of oil seals serve specific roles to maintain optimal function. This article explores the most widely used types of oil seals — valve oil seal, Victor oil seals, wall oil seal, wheel hub oil seal, and wheel oil seal — highlighting their features, benefits, and applications.

Understanding the Role of Oil Seals in Machinery

Oil seals, also known as shaft seals or grease seals, are designed to seal the openings between stationary and moving parts in mechanical equipment. Their core purpose is to:

Prevent lubricant leakage

Block contaminants like dust, dirt, and water

Maintain pressure in sealed systems

Extend machinery life by reducing wear

Without proper sealing, machines and vehicles risk premature failure, decreased efficiency, and higher maintenance costs.

Among the many types of oil seals, five stand out for their importance in the automotive and industrial sectors.

Valve Oil Seal

The valve oil seal plays a critical role in internal combustion engines. It is positioned on the valve stem, where it controls the amount of oil that lubricates the valve guide. A precise oil film is necessary to reduce wear and friction, but excess oil can burn in the combustion chamber, leading to blue smoke and carbon deposits.

Made from heat-resistant rubber or synthetic materials, valve oil seals must endure high temperatures, pressure, and chemical exposure. Properly functioning valve oil seals contribute to reduced oil consumption, better engine performance, and compliance with emission standards.

Victor Oil Seals

Victor oil seals are premium sealing products manufactured by Victor Reinz, a globally recognized brand in sealing technology. These seals are known for their exceptional quality, advanced engineering, and application-specific designs.

Whether used in engines, transmissions, axles, or industrial equipment, Victor oil seals offer superior resistance to wear, chemicals, and temperature fluctuations. They are especially favored by mechanics and engineers who require OEM-level performance and long-lasting durability.

In automotive repairs and overhauls, using Victor oil seals can significantly increase the reliability and lifespan of engines and drivetrain systems.

Types of Oil Seals and Their Applications

Wall Oil Seal

The wall oil seal (sometimes called a flange seal or face seal) is a specialized sealing solution used when a shaft runs perpendicular to a sealing surface. This design makes it ideal for applications where radial seals are impractical.

Wall oil seals are commonly used in:

Gearboxes

Hydraulic pumps

Industrial machinery with axial load

These seals are built for rugged environments and offer excellent resistance to misalignment and shaft deflection. Thanks to their sturdy design, wall oil seals are a reliable choice for sealing under pressure or when space constraints exist.

Wheel Hub Oil Seal

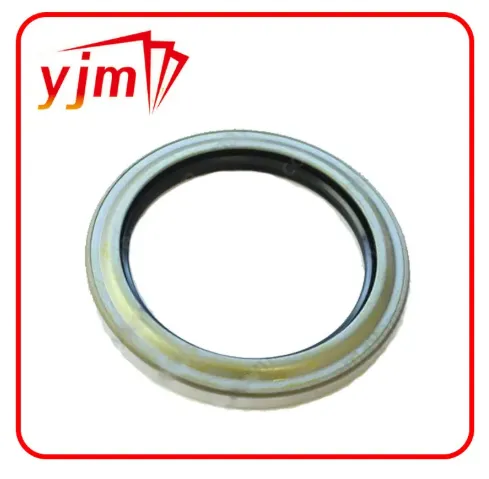

The wheel hub oil seal is essential in protecting the wheel bearings of a vehicle. Located between the wheel hub and axle, it keeps lubricants inside the bearing assembly while preventing water, dirt, and road debris from entering.

A damaged or worn-out wheel hub oil seal can lead to bearing failure, uneven tire wear, and increased rolling resistance. For heavy-duty vehicles, off-road trucks, and commercial fleets, maintaining the integrity of the wheel hub oil seal is crucial to avoid downtime and safety hazards.

These seals are engineered to resist extreme temperatures, high-speed rotation, and constant exposure to harsh road conditions.

Wheel Oil Seal

The wheel oil seal serves a similar function to the hub seal but may also refer more broadly to seals used in the entire wheel assembly, including axle and differential seals. These seals prevent gear oil or grease from leaking out of the axle housing or differential case.

In vehicles with rear-wheel or all-wheel drive systems, the wheel oil seal ensures the smooth transfer of power to the wheels by keeping the internal components well-lubricated and free from contaminants. They are particularly important in vehicles operating in tough conditions like mud, snow, or gravel.

Proper maintenance of wheel oil seals includes routine inspection for leaks, cracks, or hardening, which are signs that replacement is needed.

Benefits of Using Quality Oil Seals and Maintenance Tips

Investing in high-quality oil seals such as Victor oil seals or correctly specified valve oil seals and wheel hub oil seals has several benefits:

Reduced oil loss and extended lubricant life

Improved machinery efficiency

Longer service intervals and lower maintenance costs

Enhanced safety and reliability

To maximize the lifespan of oil seals, consider the following maintenance practices:

Regular Inspection: Check seals for visible damage, oil leaks, or unusual noises.

Proper Installation: Use appropriate tools and avoid misalignment or over-tightening.

Timely Replacement: Change seals based on manufacturer-recommended service intervals or if any signs of wear appear.

Clean Environment: Keep the sealing surfaces and surrounding areas clean during installation.

By following these simple steps, the performance and longevity of wheel oil seals, valve oil seals, and other sealing components can be greatly improved.

Oil seals may be small in size, but their impact on machinery and vehicle performance is immense. From the precision control of a valve oil seal in an engine to the robust protection offered by a wheel hub oil seal, each type serves a unique function that contributes to overall system reliability.

Choosing trusted brands like Victor oil seals, understanding the purpose of specialty types like the wall oil seal, and maintaining essential components like the wheel oil seal ensures that machines and vehicles remain efficient, durable, and safe.

Whether you're a mechanic, engineer, or equipment operator, knowing the role and value of these seals is a smart step toward optimal machine health and operational success.

Þetta er fyrsta greinin

-

Exploring Specialized Oil Seals: Key to Sealing Performance and Machinery Longevity

Fréttir Jul.16,2025

-

Essential Oil Sealing Components: Enhancing Efficiency and Durability in Machinery

Fréttir Jul.16,2025

-

Comprehensive Guide to Oil Sealing Components: From Manufacturing to High-Pressure Applications

Fréttir Jul.16,2025

-

Advanced Oil Sealing Solutions: Exploring Modern Seal Types and Applications

Fréttir Jul.16,2025

-

Advanced Oil Seal Solutions: From KOK Seals to Magnetic and Mechanical Innovations

Fréttir Jul.16,2025

-

Understanding Flat Gasket Types: A Guide to Flange, Fiberglass, and Metal Gaskets

Fréttir Jul.15,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped Plugs, Quick Drains, and More

Fréttir Jul.15,2025

Vöruflokkar