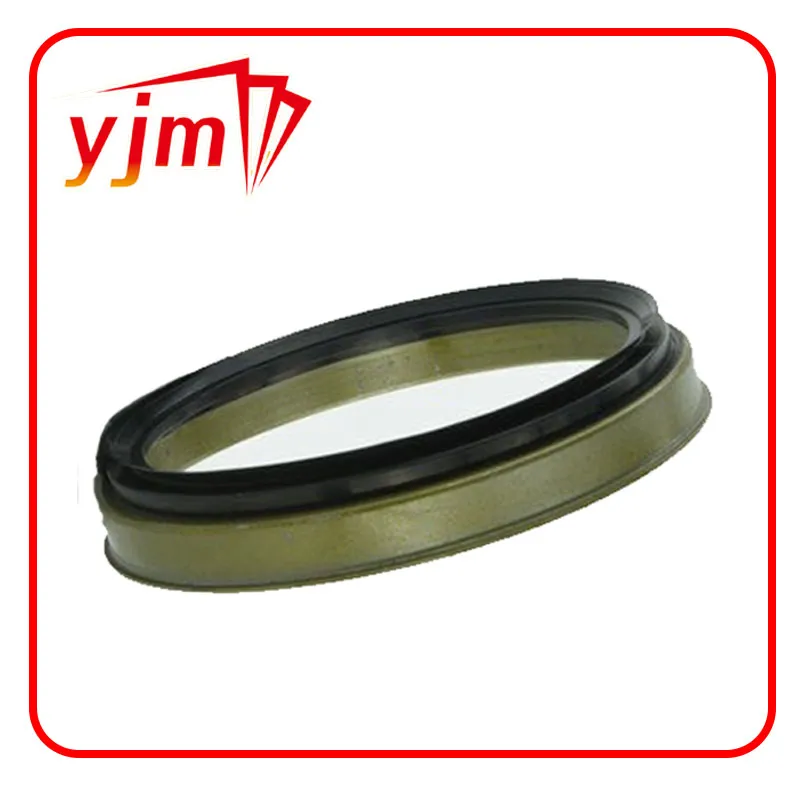

lawn mower oil drain plug

A rarely addressed issue is the cross-threading of the drain plug during reinsertion. Always take the time to hand-thread the plug at the start before applying a wrench, reducing the risk of cross-threading and ensuring a snug fit. Over-tightening can strip the threads, necessitating replacement of both the plug and possibly the oil pan. Opt for a torque wrench to apply consistent pressure, preserving both the plug and the oil pan threads, and ensuring a perfect seal. The importance of the oil drain plug goes beyond immediate maintenance needs. In terms of environmental impact, improperly disposed oil can harm local ecosystems. When draining oil, securely store it in containers to ensure safe disposal at a recycling center. The environmental responsibility of proper disposal counteracts potential damage, underscoring the drain plug's secondary role in sustainable mowing practices. Trustworthiness and credibility are paramount; always use parts and tools recommended by your mower's manufacturer. I have personally witnessed situations where inexpensive, incompatible drain plugs resulted in premature mower repairs. Original manufacturer parts promise compatibility and durability, bolstering your lawn mower's performance. In summary, understanding your lawn mower's oil drain plug is akin to knowing your mower's heart. It supports your mowing machine by ensuring timely and efficient oil changes, which foment optimal performance and durability. Comprehending its value promotes expert maintenance habits, accountability, and respect for environmental sustainability, thus marrying adeptness with trusted execution. Always remember that this small yet significant component is a cornerstone in the effortless operation of your lawn mower.

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

-

How to Identify and Fix Oil Filter Mount and Housing Gasket Leaks

News Jul.28,2025

-

Fixing Oil Housing Gasket Leaks: A Guide to Replacing Your Oil Filter Housing and Gaskets

News Jul.28,2025

-

Everything You Need to Know About Changing Your Oil Filter Housing Gasket and Related Gaskets

News Jul.28,2025

-

Essential Kits and Tools for Engine Repair and Enhancement

News Jul.28,2025

-

Diagnosing and Fixing a Leaking Oil Filter Housing Gasket: What You Need to Know

News Jul.28,2025

-

Understanding Flat Gaskets: Types, Materials, and Industrial Applications

News Jul.25,2025

Products categories