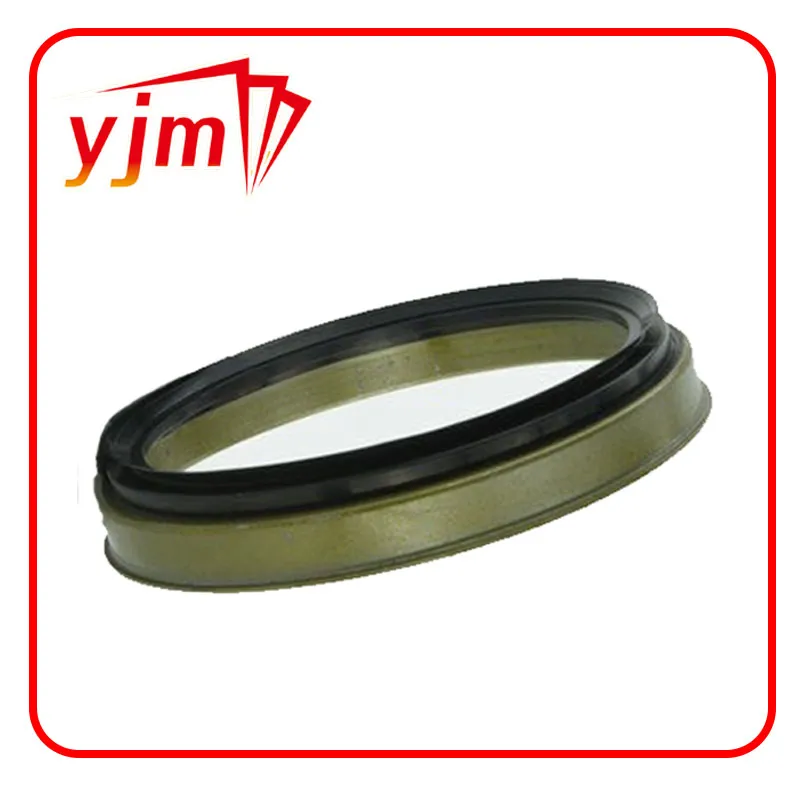

31x43x10 5 oil seal

Authority in the field of oil seals does not merely stem from understanding product specifications but also from a comprehensive knowledge of their applications. Industry experts advocate for a proactive maintenance schedule incorporating regular checks and timely replacements of oil seals to circumvent potential operational halts. By minimizing friction between moving parts and preventing lubricant escape, oil seals like the 31x43x10 5 are essential in enhancing machinery lifespan, reducing the total cost of ownership over an asset's life. Trustworthiness of oil seals, including the 31x43x10 5, is predicated on rigorous manufacturing standards and quality assurance. Reputable manufacturers engage in stringent testing processes, subjecting their products to various stress, temperature, and pressure conditions to certify their reliability and durability. It is advisable to source seals from certified suppliers whose production processes adhere to international standards, guaranteeing performance consistency and safety. In a world where operational efficiency is the linchpin of competitive advantage, the seemingly inconspicuous oil seal assumes a role of paramount importance. The 31x43x10 5 oil seal, with its specialized dimensions and material versatility, is a testament to engineering ingenuity aimed at solving nuanced challenges in machinery operations. For engineers and maintenance experts navigating the intricacies of equipment management, investing in quality oil seals pays dividends through reduced downtime, enhanced machinery performance, and ultimately, a robust bottom line. In summation, the 31x43x10 5 oil seal stands out not only for its technical specifications and reliable performance but also for the peace of mind it delivers to those that rely heavily on uninterrupted machine operations. By prioritizing quality and suitability, businesses can safeguard their assets and maintain their competitive edge in an ever-evolving industrial landscape.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories