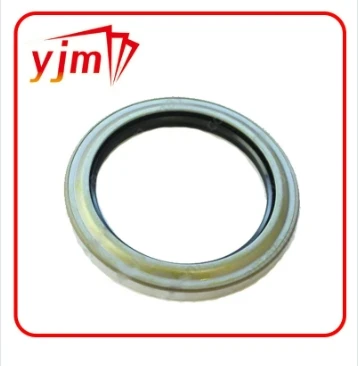

oil seal manufacturers in china

Authoritativeness in this sector is further reinforced by compliance with international quality standards and certifications. Many Chinese oil seal manufacturers hold ISO, TS16949, and RoHS certifications, ensuring their products not only meet global benchmarks but also adhere to sustainable and environmentally friendly practices. Such credentials are indicative of a commitment to maintaining quality and consistency, essential traits for maintaining competitive advantage on the global stage. Furthermore, collaborations with international clients and participation in global trade exhibitions allow these companies to stay abreast of the latest industry trends and technologies. Trustworthiness is quintessential for fostering long-term business relationships, and Chinese oil seal manufacturers demonstrate this through transparency, consistent quality, and robust after-sales support. Many companies offer comprehensive warranties and dedicated customer service teams to address any concerns swiftly. This dedication to customer satisfaction builds trust and encourages enduring partnerships. Additionally, leveraging modern supply chain management systems ensures timely delivery and reliable product availability, which is crucial for businesses operating on tight schedules and margins. In conclusion, the oil seal manufacturing landscape in China is shaped by a combination of experience, expertise, authoritativeness, and trustworthiness. By continually advancing their production capabilities and prioritizing quality, Chinese manufacturers are well-positioned to meet the ever-evolving needs of global industries. As the demand for efficient, sustainable, and high-performance sealing solutions grows, these companies remain at the forefront, exemplifying the high standards and reliability the global market has come to expect.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories