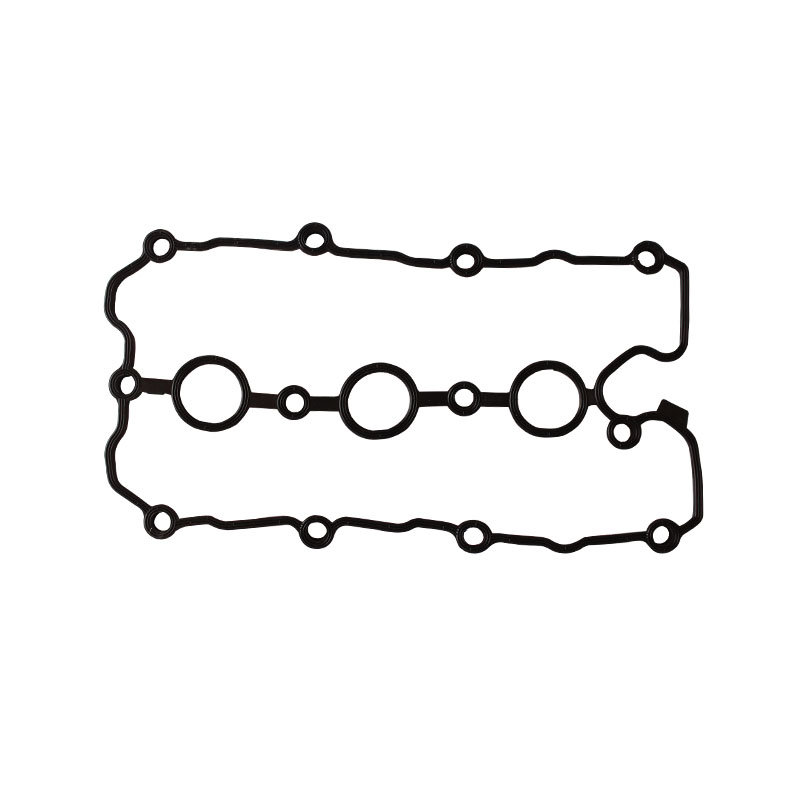

Seal oil filter housing Engine Side BMW Petrol 11427537293

Seals are not immune to damage from external factors. Harsh driving conditions, such as off-road or high-speed terrains, can accelerate wear and tear. Environmental elements like dust, dirt, and road salt can also erode the seal’s integrity over time. Consequently, adapting driving habits and regular cleaning can reduce these risks. Automotive bloggers and enthusiasts suggest using appropriate car covers and performing frequent washes, especially after exposure to muddy or salty conditions, as practical measures to preserve the seal's condition. Replacement of a damaged seal is a process best left to professionals. Although the average auto enthusiast may successfully replace basic vehicle components, the seal’s placement typically demands technical expertise, specialized tools, and knowledge of the vehicle's drivetrain layout. Professional installation ensures that the new seal is properly seated, aligned, and capable of enduring the vehicle’s specific mechanical demands. In summary, the seal between a motor and transmission is a deceptively simple yet indispensable component within a vehicle's drivetrain. Acting as a barrier against leaks and contaminants, it promotes efficient operation and reduces the potential for costly failures. Experts consistently advocate for routine inspections, mindful driving habits, and professional replacements to maintain this critical part’s function. As technology evolves, staying informed on emerging materials and methods related to these seals ensures that vehicle owners can make educated maintenance and repair choices. Ultimately, these proactive approaches anchor a trustworthy and authoritative foundation for vehicle longevity and performance.

-

Understanding Flat Gaskets: Types, Materials, and Industrial Applications

News Jul.25,2025

-

Understanding Bonded Seals: Types, Applications, and Industrial Advantages

News Jul.25,2025

-

The Complete Guide to Flat Gaskets: Materials, Uses, and Applications

News Jul.25,2025

-

Sealing Solutions: A Comprehensive Guide to Flat Ring Gaskets and Seals

News Jul.25,2025

-

Flat Gaskets Explained: Materials, Applications, and Best Uses

News Jul.25,2025

-

Everything You Need to Know About Automotive Drain Plugs and Oil Pan Maintenance

News Jul.25,2025

-

Understanding Oil Drain Plugs: Quick, Universal, and Self-Tapping Options for Every Engine

News Jul.24,2025

Products categories