Flat Gaskets Explained: Materials, Applications, and Best Uses

Flat gaskets are essential sealing components used in everything from industrial machinery to home appliances. Known for their versatility and simplicity, flat gaskets serve as a barrier between two flat surfaces, preventing leaks of liquids, gases, or other media. Whether you're working on high-temperature equipment like stoves or simply replacing a household seal, understanding the right flat gasket material is crucial. This article explores the different types of flat rubber gaskets, the importance of choosing the proper flat rubber seal, and how materials like wood stove flat gasket material can enhance performance in specific applications.

What Is a Flat Gasket and Where Is It Used?

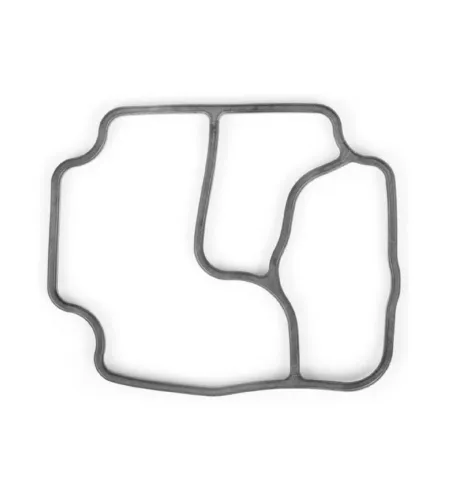

A flat gasket is a flat-shaped sealing component, typically placed between two surfaces to prevent leakage during compression. Unlike O-rings or molded seals, flat gaskets are cut from sheet materials and tailored to the application.

Versatile Design: Flat gaskets can be made in many shapes and sizes, including rings, squares, or custom designs, to fit flanges, machine parts, or appliance doors.

Broad Industry Use: They are widely used in plumbing, automotive, HVAC, chemical processing, and household applications.

Simple Installation: Their flat profile makes them easy to install and replace, especially in flanged joints and static sealing conditions.

Because of their low cost and adaptability, flat gaskets are one of the most common sealing solutions across industries.

Types and Benefits of Flat Rubber Gaskets and Flat Rubber Seals

Rubber is among the most popular materials for flat gaskets due to its flexibility, sealing strength, and affordability. Flat rubber gaskets are ideal for medium to low-pressure environments, offering a tight seal even in systems with vibration or surface irregularities.

Flat Rubber Gaskets

These are widely used in general-purpose sealing tasks, such as:

Water and Air Systems: Common in faucets, valves, and pipes to prevent leaks.

Machinery and Engines: Used to seal fluid compartments or cover plates.

Home Appliances: Found in dishwashers, washing machines, and refrigerators.

Materials used in flat rubber gaskets include:

Nitrile (Buna-N): Excellent for oil and fuel resistance.

EPDM: Great for weather, steam, and UV resistance.

Neoprene: Good for ozone and moderate chemical resistance.

Silicone: High-temperature capability and food-grade options available.

Flat Rubber Seal

The flat rubber seal refers to any gasket or sealing layer made from rubber that lies flat between two surfaces. While similar in appearance to a gasket, seals are often designed for dynamic applications as well, such as:

Rotating Shafts and Doors: Where motion occurs between sealing surfaces.

Lids and Covers: To provide pressure-sensitive airtight or watertight closure.

Both flat rubber gaskets and flat rubber seals provide cushioning and excellent sealing properties, making them indispensable in both static and mildly dynamic environments.

Choosing the Right Flat Gasket Material for Performance and Safety

The performance of any gasket depends heavily on its material. Not all flat gaskets are created equal—specific applications demand certain qualities like heat resistance, flexibility, or chemical stability. Let’s break down some common flat gasket material options, including those used for wood stoves.

General Flat Gasket Material

These are used in a wide variety of applications:

Rubber Sheets: Ideal for water, air, and low-pressure systems.

Cork-Rubber Composites: Offer high flexibility and compressibility.

Graphite: Suitable for high-temperature and chemical resistance in industrial use.

PTFE (Teflon®): Excellent chemical inertness and temperature tolerance.

When selecting a flat gasket material, always consider:

Operating temperature

Chemical exposure

Pressure level

Compression requirements

Flat Rubber Gasket Material

This refers specifically to rubber-based materials cut into flat gasket shapes. It is selected for its:

Elastic Recovery: Ability to maintain a seal even after deformation.

Environmental Resistance: Withstands water, weather, oil, and mild chemicals.

Wide Availability: Sold in sheets or pre-cut shapes, suitable for DIY and industrial uses.

If you’re repairing plumbing or assembling mechanical components, choosing the correct flat rubber gasket material ensures longevity and leak prevention.

Wood Stove Flat Gasket Material

Wood stoves operate under high heat and demand materials that can maintain their sealing properties under thermal stress. Common wood stove flat gasket material includes:

Fiberglass: A high-temperature option, flexible and strong, used around doors and panels.

Graphite-Impregnated Rope or Tape: Enhances sealing and longevity under constant heating cycles.

Vermiculite or Ceramic Fiber: Less common but extremely heat-resistant.

Replacing a worn stove door gasket with the right wood stove flat gasket material ensures efficient combustion, prevents smoke leakage, and maintains safety.

Final Thoughts

Whether you're sealing an engine, a pipe joint, or a wood stove, flat gaskets are essential tools for creating reliable, long-lasting seals. From general-purpose flat rubber gaskets to high-heat wood stove flat gasket material, each type of gasket plays a specific role in protecting your equipment and ensuring operational safety.

By understanding the differences in flat gasket material, and knowing when to use a flat rubber seal versus a high-performance gasket, you can ensure better performance, reduce maintenance needs, and avoid costly breakdowns. Choose wisely, and your systems will stay sealed, secure, and safe.

-

Seal 12x20x5: Precision Radial Shaft Seals for Industrial Reliability

Novas Nov.24,2025

-

Seal 12x18x5: Essential Guide to Specifications, Applications & Vendors

Novas Nov.24,2025

-

Understanding Seal 12 20 5: Applications, Specifications & Industry Insights

Novas Nov.23,2025

-

Durable Oil Seal 85x110x12 – Reliable Sealing Solutions for Industry

Novas Nov.23,2025

-

Durable and Precise Oil Seal 75x95x10 for Efficient Machinery | YJM Seal

Novas Nov.22,2025

-

Durable Oil Seal 75x100x10 for Reliable Industrial Performance | YJM Seal

Novas Nov.22,2025

-

High-Quality Oil Seal 65x90x10 | Durable & Reliable Sealing Solutions

Novas Nov.22,2025

Categorías de produtos