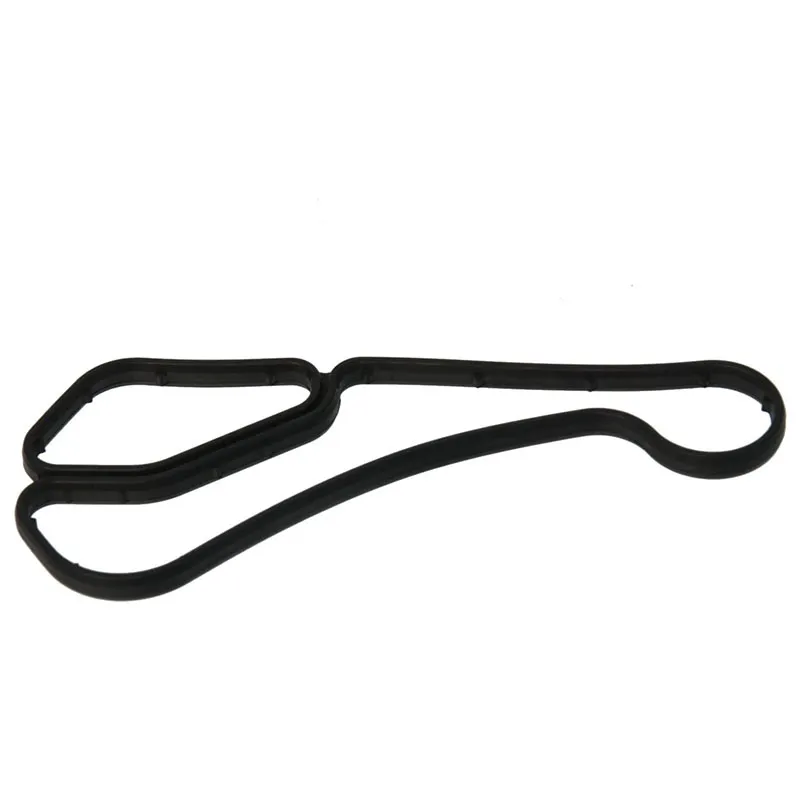

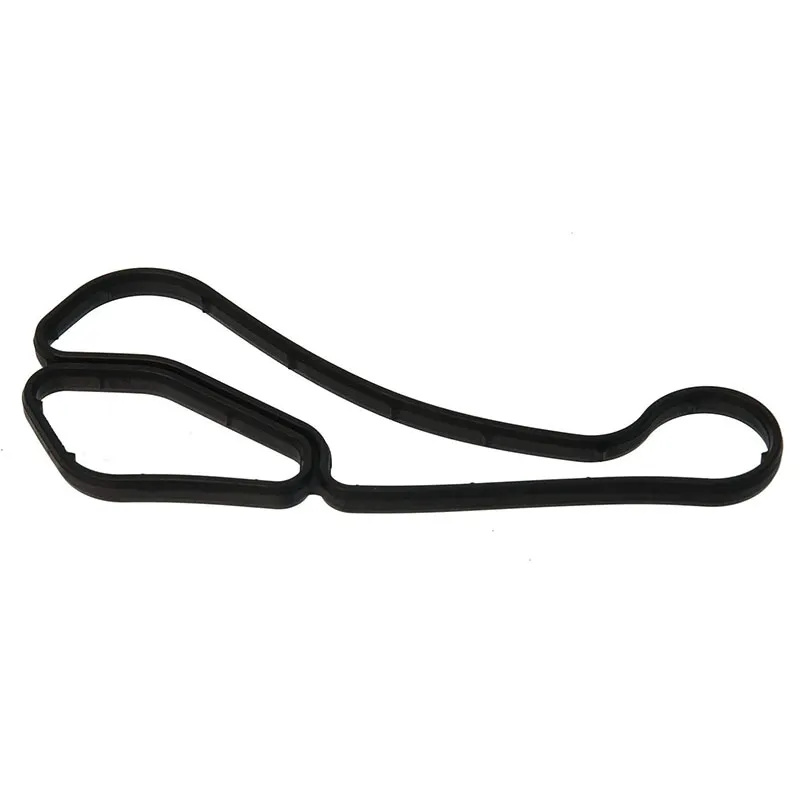

High-Quality Oil Cooler Gasket for Oil Cooler to Oil Filter Housing 11427525335

Industry Trends: Evolving Demands for Oil Cooler Gasket

- Material Upgrades: Transition from standard rubber to advanced fluoroelastomers (e.g. FKM), PTFE, and composite graphite gaskets.

- Process Modernization: widespread CNC precision machining and laser cutting for manufacturing gaskets with micron-level tolerances.

- Certification: Compliance with ISO 9001, ISO/TS 16949 for automotive, ANSI and FDA standards for industrial and petrochemical usage.

Technical Specifications: Oil Cooler Gasket Parameters Overview

| Parameter | Oil Cooler Gasket 11427525335 | Standard Rubber Gasket | PTFE Sealing Gasket |

|---|---|---|---|

| Material | Fluoroelastomer (FKM) / NBR / Graphite Composite | NBR/Rubber | PTFE |

| Max Operating Temp | Up to 230°C (446°F) | ~120°C (248°F) | 260°C (500°F) |

| Pressure Resistance | 2.5 - 4.2 MPa | 1.0 - 2.0 MPa | 2.0 - 3.5 MPa |

| Chemical Resistance | Excellent (oil, fuels, acids) | Fair | Outstanding |

| Compression Set (@150°C) | <15% | ~22% | <10% |

| Life Expectancy | 60,000 - 100,000 hours | 25,000 - 40,000 hours | 65,000 - 120,000 hours |

| Certification | ISO 9001, TS16949, (if required: FDA, ANSI) | ISO 9001 | FDA, ISO 9001 |

| Application | Oil cooler/filter, metallurgy, chemical, automotive | Standard water/oil seal | Corrosive/food/medical/chemical |

Manufacturing Process Flow: Oil Cooler Gasket

- Material Selection: Only high-grade Fluoroelastomer (FKM), NBR or graphite-based compounds certified to ISO 9001/TS16949 are used for optimum thermal and chemical resistance.

- Compounding: Custom compounding is done in dedicated mixers to ensure precise polymer-to-additive ratios for durability and anti-aging. Meets ASTM D2000 rubber standards.

- CNC/Cutting/Forming: Advanced CNC cutting and compression molding, achieving shape tolerances <0.05mm, minimal surface roughness & superior reproducibility.

- Curing/Vulcanizing: Exact vulcanization profiles optimize cross-linking, maximizing elasticity and sealing. Fully automated lines guarantee batch consistency.

- Inspection & Testing: 100% product undergoes leak, tensile, and oil immersion testing per ISO 16128, ASTM D395 for compression set, and SAE J1993 for automotive seals.

- Packing & Delivery: Automated packaging under cleanroom ISO Class 8 environment prevents dust/oil contamination.

Key Technical Parameters & Trend Visualization

Application Scenarios & Advantages: Real Industry Cases

- Automotive Engines: Oil Cooler Gasket applied in BMW, Ford and Mercedes models for reliable oil separation and prevention of external leakage at the oil cooler-module joint; reduces maintenance cost by 20% and allows service intervals up to 95,000 km.

- Oil & Gas Refineries: Used to withstand high-temperature, high-acidity lubricants in flow separators. Third-party tests show leakage drop to 0.002 ml/h (ISO 23936-2).

- Steel/Metallurgy Industry: Proven life extension of sealing units by 1.6x, even under continuous operation at 210°C, reducing unplanned downtime significantly.

- Municipal Waterworks: In high-chlorine environments, anti-oxidation layers prevent gasket embrittlement for up to 7 years without replacement.

Manufacturer Comparison: Why Choose Our Oil Cooler Gasket?

| Factor | YJMseal 11427525335 | Other Domestic Brands | International Brands |

|---|---|---|---|

| Material Control | 100% imported FKM, ISO/TS16949 certified | Mixed; often no ISO/ANSI | Imported, ISO standards |

| Manufacturing Tech | CNC, Laser Cutting, Vulcanizing press | Stamping, Manual molding | CNC, Automated molding |

| Dimensional Accuracy | <0.03 mm | ~0.10 mm | ~0.05 mm |

| Batch Consistency | Full SPC traceability, batch test data | Partial sampling | Computerized traceability |

| Pressure/Temp Test | 100% tested, 4.2MPa at 230°C for 48h | Sample test only | Batch tested at rated values |

| Lead Time | 5-7 working days | 14-21 days | 8-12 days |

| Warranty | 24 Months | 6-12 Months | 12-24 Months |

| OEM/ODM Capability | YES (custom marking, size, compound) | Limited | YES |

Customization: Tailor Your Oil Cooler Gasket Solution

- Material: FKM, HNBR, NBR, PTFE, EPDM, Graphite.

- Shore Hardness: 60-85A. Certified per ASTM D2240.

- Color: Black, Brown, Custom.

- Dimension: Tolerance as tight as ±0.03mm for fit-critical applications.

- Coating: Optional: Graphite, Anti-friction, Phosphate.

- OEM Marking: Laser logo/text or custom packaging.

Application Case: Client Feedback & Service Record

A major European OEM adopted YJMseal Oil Cooler Gasket for their 2022 vehicle platforms. After a 24-month field trial and 95,000km test mileage, zero leakage was observed. The maintenance record documented a 25% decrease in unplanned gasket replacements, directly impacting downtime costs and aftermarket satisfaction.

Petrochemical pump stations using customized graphite-filled gaskets observed a doubling of seal longevity, as per maintenance logs. Feedback from engineering teams highlighted exceptionally low penetration rates (<0.001 ml/h, verified via ISO 23936-2).

A national water utility reported that over 4 years, gasket change intervals were extended from 1.5 to 6 years, mainly due to the durable anti-aging properties of FKM blends. This resulted in a 35% reduction in annual gasket maintenance expenditure.

FAQ: Oil Cooler Gasket Professional FAQ

Delivery & Warranty Commitment: Trustworthy Service

- Delivery: All stock models ship within 5-7 days. Custom orders: 10-15 working days.

- Warranty: 24 Months against material and workmanship defects (referenced to ISO 6147 guidelines).

- Technical Support: Lifetime email/phone support, installation video/manual. Full traceability by serial and lot.

- Quality Documentation: Each batch can be supplied with RoHS, REACH, MSDS certificates and test reports (ISO/ASTM compliant).

- Anti-Counterfeit: Optional QR/laser batch tracking against counterfeiting for key sectors.

[1] "Oil Sealing Technology & Materials: Current Trends and Testing (2022)", Journal of Elastomeric Engineering. Read more

[2] "Oil Cooler Market by Equipment & Component - Forecast to 2027", MarketsAndMarkets. View source

[3] "Seal and Gasket Performance: Standard Comparison", Industrial Gasket Forum. Visit Forum

-

Seal 12x20x5: Precision Radial Shaft Seals for Industrial Reliability

News Nov.24,2025

-

Seal 12x18x5: Essential Guide to Specifications, Applications & Vendors

News Nov.24,2025

-

Understanding Seal 12 20 5: Applications, Specifications & Industry Insights

News Nov.23,2025

-

Durable Oil Seal 85x110x12 – Reliable Sealing Solutions for Industry

News Nov.23,2025

-

Durable and Precise Oil Seal 75x95x10 for Efficient Machinery | YJM Seal

News Nov.22,2025

-

Durable Oil Seal 75x100x10 for Reliable Industrial Performance | YJM Seal

News Nov.22,2025

-

High-Quality Oil Seal 65x90x10 | Durable & Reliable Sealing Solutions

News Nov.22,2025

Products categories