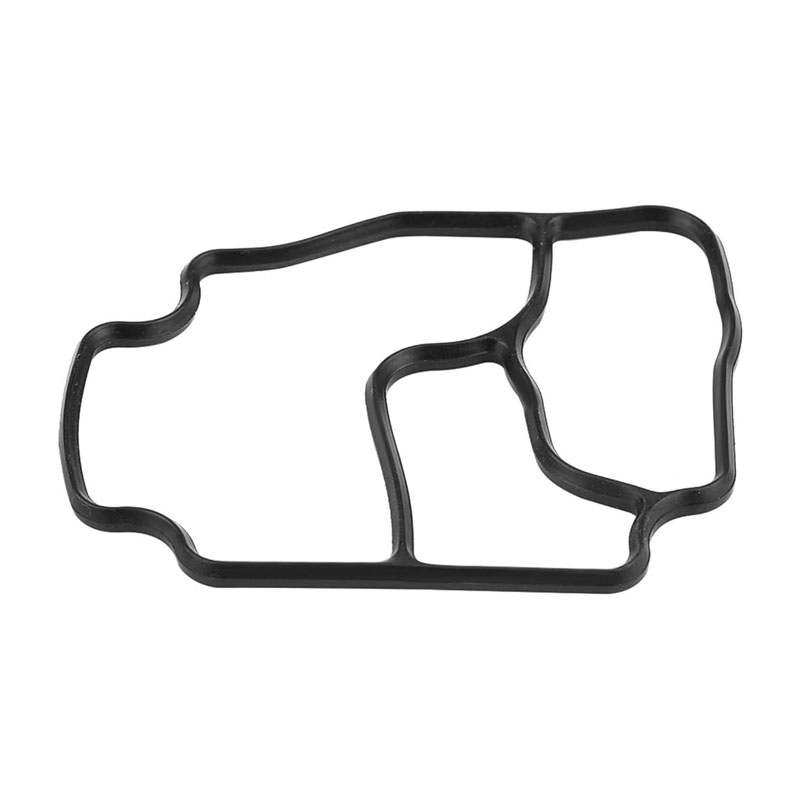

pan seal

Innovation continues to revolutionize the way stuffing box seals are integrated into industrial applications. Recent developments have seen the inclusion of monitoring sensors within stuffing boxes, providing real-time data on seal integrity and potential failure alerts. This proactive approach allows maintenance teams to address issues before they exacerbate, ensuring operational continuity. Such technological advancements reflect the growing expertise harnessed within the field to meet modern industrial challenges. For manufacturers and engineers aiming to optimize their systems, considering a stuffing box mechanical seal is not only about selecting a product but also understanding the ecosystem of maintenance, material compatibility, and installation precision required. By fostering a deeper understanding of these aspects, industry professionals can ensure stuffing box seals deliver the necessary performance and reliability expected in today's demanding environments. In an era where optimization is synonymous with sustainability, implementing the right stuffing box mechanical seal effectively reduces waste and enhances the overall ecological footprint of industrial operations. As industries evolve, the continuous drive for more sustainable practices will likely boost innovation in this space, emphasizing the need for ongoing expertise and adaptation to emerging technologies and methodologies in sealing solutions. Ultimately, incorporating the right stuffing box mechanical seal into your industrial operations necessitates a blend of experience, expertise, and trustworthiness. By prioritizing these elements, businesses not only safeguard their equipment and productivity but also align themselves with market leaders who drive innovation and set benchmarks in mechanical seal technology.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories