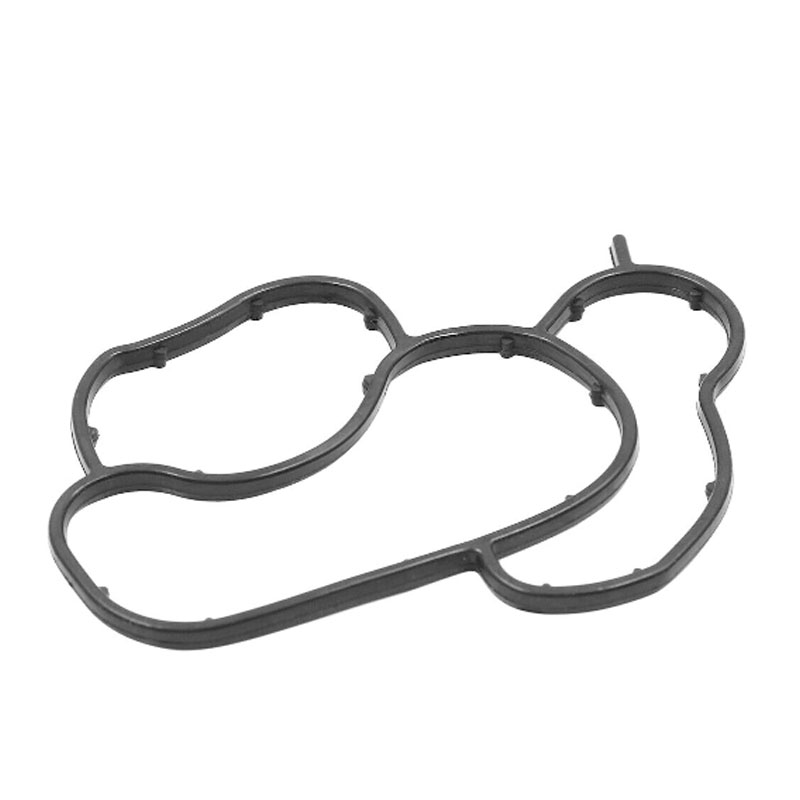

flat metal ring gasket

The aerospace industry further exemplifies the expertise ingrained in FFPM O-ring applications. Aircraft operate under extreme pressures and temperatures, with components expected to perform flawlessly over long durations. FFPM O-rings contribute significantly to the safety and reliability of such high-stakes equipment. Their resilient properties allow them to maintain seals under rapid temperature shifts and variable pressures encountered during flight, ensuring the safety of both the crew and the aircraft. FFPM O-rings also shine in semiconductor manufacturing, an industry where miniaturization and efficiency reign supreme. The manufacturing process involves the use of aggressive chemicals and plasmas, and any contamination can lead to costly defects. FFPM O-rings offer the precision and resistance needed to handle this environment, thus playing a crucial role in ensuring product quality and operational reliability. Drawing from decades of application experience, FFPM O-rings have proven their worth across these diverse industries. They offer more than just a mechanical seal — they provide a blend of expertise and reliability that is integral to modern industrial operations. Their development and continued usage underscore the intersection of advanced material science and engineering acumen, a testament to innovation that serves global technological and industrial progress. In conclusion, for businesses seeking efficiency in extreme environments, FFPM O-rings emerge as the authoritative choice, rooted in authenticity and backed by a track record of success. Their role, often operating behind the scenes, reflects an amalgamation of experience, professional expertise, and trust that businesses worldwide have come to rely on. This level of reliability not only optimizes performance but also significantly mitigates potential risks associated with equipment failure, presenting investors and stakeholders with a component that embodies both financial prudence and operational excellence.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories